Bond Line Read-Through: What It Is and How to Prevent It

Bond line read-through is a major source of frustration for any fabricator that works with thin metals or plastics. But solutions to this problem are hard to come by. In this post, we break down the causes of bond line read-through and how you can eliminate it from your fabrications.

What is Bond Line Read-Through?

Bond line read-through, also known as telegraphing, is a condition where you can see the footprint of the adhesive through the material. It occurs when an adhesive has a distorting effect on a metal. (More on that in a bit.) This distortion turns aesthetically pleasing products into unsightly ones.

There are a number of materials that are susceptible to bond line read. Aluminum composite materials (ACM) and metal composite materials (MCM) are most associated with this problem, but bond line read-through is a problem for many other metals used for aesthetics including thin-gauge metals and composites.

Metals panels .03” thick or less are most susceptible to bond line read-through but the issue can affect metals of a variety of thicknesses depending on the adhesive used and the application. Generally speaking, larger panels, darker colors and glossier finishes will create more exaggerated line read through. For example, a panel that’s large, black and glossy is going to have easily visible distortion issues.

Prefinished metals and decorative metals such as mirror finish stainless steel or brushed aluminum are also likely to be affected, as the slightest imperfections can be painfully obvious on these types of finishes.

What Causes Bond Line Read-Through?

Conventional structural adhesives, such as methyl methacrylates (MMAs) go through a curing process that involves a chemical reaction. Typically two components, a resin and a curative or activator, are mixed and, as the adhesive cures, heat is generated. This is called an exothermic reaction. During the reaction, the adhesive may expand slightly due to the heat that is produced, and after the reaction is complete the adhesive will shrink.

Bond line read-through occurs because of the heat produced, the amount of shrinkage that occurs and because the adhesive does not have enough flexibility to compensate. Essentially, the properties of the adhesive used are not designed explicitly for bonding thin-gauge materials

Here is what typically happens when you apply a conventional MMA adhesive to a metal like ACM:

- As the adhesive cures, heat is generated

- This reaction heats the plastic core of the ACM, making it susceptible to bending.

- As the core softens, it expands.

- When the adhesive finishes curing, it cools and shrinks back.

- The shrinkage creates a pull on the bonded materials.

- The thin and softened ACM can’t resist the force and shrinks with the adhesive.

This shrinkage creates a rippling effect that can make the finished product look beat up or damaged. If you hold the distorted sheet up to the light and look at the reflection in the image, you’ll see waves in it. This distortion ruins the aesthetics on the fabrication.

Can You Fix Bond Line Read-Through?

Once you fabricate a sheet with bond line read-through, you don’t have many options when it comes to fixing it.

Technically, you could heat up the adhesive and try to separate the parts. But with a thin sheet of metal, you’re probably going to damage it further. Plus, heating it up may cause more distortion.

So, given that you can’t repair the distortion, you have two choices: Deliver an inferior product or scrap it entirely. Both options are unfavorable to your costs and reputation.

This is why the best way to deal with read-through is to prevent it from happening in the first place.

Using Low Read-Through Adhesives

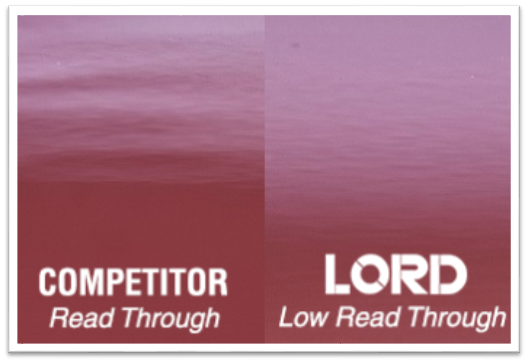

|

|

| ACM part bonded with conventional MMA |

ACM part bonded with LRT adhesive |

The best way to prevent bond line read-through is to use an adhesive that is designed to eliminate it. Sounds simple, right?

To prevent bond line read, you need an adhesive with the following features:

- Consistent bond line thickness

- Low thermal footprint

- Low shrinkage

- High elongation

Despite the widespread challenge bondline read-through poses for this industry, there are very few products that address all of these requirements. One example is the Lord 810/20, which we’ll now use to demonstrate.

The Lord 810 is a structural, low-read-through (LRT) adhesive designed to prevent read-through while reducing human error and variability in the system. It does so in four ways.

Consistent Bond Thickness

Lord 810 is formulated with 10mm thick glass beads that are used in the adhesive. This guarantees ideal bond line thickness, one of the most important requirements for preventing bond line read. This eliminates the possibility of over clamping or over weighting, making your fabrication consistent. There are very few products that use glass beads to this effect.

Low Thermal Footprint

An adhesive with a lower thermal footprint won’t melt the plastic composite, preventing warping. A structural adhesive like Lord’s has a low heat, low warp profile.

Low Shrinkage

One of the biggest causes of bond line read is the amount of shrinkage that occurs when an adhesive cures. A conventional acrylic adhesive has 8-15% shrinkage. In contrast, a structural adhesive like the Lord 810 has 5% or less shrinkage. This allows you to exert 2-3x less force on your materials.

High Elongation

A LRT adhesive also delivers much higher flexibility, placing lower stress on the materials. While a conventional acrylic might have elongation of 15-40%, Lord 810 features 190% elongation. This allows the adhesive to compensate for some expansion and contraction during curing without deforming the metal, unlike alternatives that are so rigid that all of the stress is transferred to the metal.

In summary, if you are able to find a structural adhesive that delivers these four features, you can prevent bond line read-through in a system with minimal variability.

Additional Tips and Best Practices

When fabricating a thin materials, there are a few additional tips and tricks you can use to avoid bond line read through:

- Use a fixturing method that applies pressure evenly across the surface to avoid high spots or low spots. Be careful not to over-clamp and squeeze out all or most of the adhesive. This could result in a starved joint that does not have the required structural strength

- If using weights, evenly distribute the weights you’re using to press down the materials during curing.

- Shoot for an even and consistent bondline thickness of .010”.

- Make sure to store the adhesives are room temperature ( ≈ 70°F) to ensure proper curing speeds

- Follow the proper steps to load, level and purge the cartridge prior to us

Conclusion

Bond line read-through can make it difficult to achieve the results you want to see in your products. But with the right system and the right adhesive, you can eliminate this problem and provide enhanced aesthetics for your commercial construction fabrications.