Not All Silicones are Created Equal

In the world of sealants and adhesives, silicone has emerged as a versatile and indispensable material. Its ability to maintain flexibility under various temperatures, resist moisture, and provide excellent adhesion has made it a preferred choice for countless applications. However, not all silicones are created equal, and it’s crucial for consumers and professionals alike to be aware of the differences between quality silicone and subpar, cheap silicone alternatives flooding the market, particularly from Turkey and Korea.

At first glance, these imported silicones might seem like a bargain with their lower price tags. Still, as the old saying goes, “you get what you pay for.” These cheaper alternatives can cause more harm than good in the long run. Here are some key factors that distinguish quality silicone from its inferior counterparts:

Net Fill & Shrinkflation

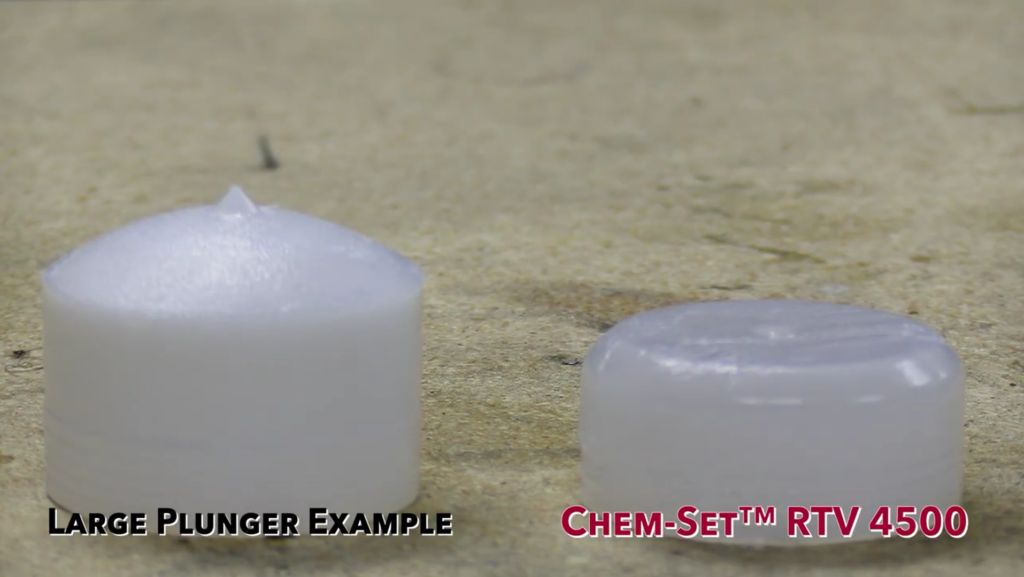

One of the most common tactics employed by manufacturers of inferior silicone products is to reduce the net fill in a tube or cartridge. Some silicone sealants on the market may have less than 10 oz of product in the tube. We have seen the use of larger plungers that are double the height of standard ones to create the illusion of a fuller cartridge. This deceptive practice allows low cost providers to cut costs while selling what appears to be a similar product at a reduced price. You might have seen similar tactics with products in the grocery store where the prices stay the same but the volume of product in the package is less and less.

Extended Silicone vs 100% Silicone

Additionally, there’s the matter of extended vs. 100% silicones.

Extended silicones are typically mixed or cut with more filler material, such as oil and solvents, making them less effective and less durable in the long run. The percentage of distillate material in a silicone (around 30-40%!), can significantly affect its quality, as it makes it more prone to shrinking over time. This will weaken their bond, and compromise their overall performance. In addition, extended silicones may change color or develop inconsistencies as they age.

100% silicones, on the other hand, are not cut with these fillers, and provide superior performance. Quality silicone is known for its minimal shrinkage upon curing, superior strength/adhesion, flexibility, and durability, even in harsh conditions. They are less likely to crack, or become brittle. Furthermore, 100% silicone is resistant to moisture and weathering, such as UV rays, water, sunlight, or other extreme weather conditions. This allows it to maintain a consistent color and appearance over time.

One simple yet effective test to identify quality silicone is the float test. Simply place the cartridge of the silicone you want to evaluate in water. High-quality silicone will sink when placed in water, while lower-quality alternatives will float.

Specialized silicones:

We have discussed the term 100% silicone and how to contrast 100% products with extended products. But this is not the whole story. Within single component silicone sealants, there are four main types. Acetoxy, oxime, alkoxy, and acetone. Acetoxy silicones are the most common and most of the silicone you might find at the hardware store or in the building trades fall into this category. You can tell an acetoxy silicone if it has that distinctive vinegar type smell. Acetoxy silicones are suitable for many applications and there are many high quality examples of this type of product. However some applications call for more specialized products. For instance, when used on some types of natural stone including quartzite and marble, acetoxy silicone can cause staining or bleeding which can become an expensive problem. For these sensitive stones, an oxime or neutral cure silicone is recommended. There are also grades of silicone specifically designed for use in electronics, where acetoxy based products can damage sensitive parts. This all goes to show that not all silicone is created equal. If you are unsure of the right product to use, you should check an adhesive and sealant expert!

Conclusion

While the allure of lower-priced silicone products made overseas may be tempting, it’s essential to exercise caution and consider the long-term implications. Investing in quality silicone not only ensures better performance and durability but also peace of mind. So, remember the adage “buyer beware” and make informed decisions when choosing silicone products for your projects. It’s a choice that can save you time, money, and headaches down the road.

These are the products we recommend for premium-grade silicone solutions. When it comes to your projects and applications, these choices promise exceptional performance, durability, and peace of mind.

-

Sikasil GP-101 RTV SiliconeOur Price Starting at From: $6.10

Sikasil GP-101 RTV SiliconeOur Price Starting at From: $6.10 -

Chem-Set RTV4500 100% Silicone – Standard ColorsOur Price Starting at From: $5.17

Chem-Set RTV4500 100% Silicone – Standard ColorsOur Price Starting at From: $5.17