How the Xcelerate Complex42 is Transforming Drilling and Tunneling

The Xcelerate Complex42 is a revolutionary cutting additive allowing exponential improvements in performance for hard rock drilling in mining, geotechnical and tunneling operations.

When added to water, it creates a unique mechano-chemical reaction between the cutting surface and the rock, which decreases the hardness and the ductility of the material being cut. This allows the cutting and grinding to be done at a much higher speed.

This additive promises not only significant enhancements in drilling speed but also ensures fewer drill string jams and an extended lifespan for both diamond tools and machinery.

Key Technical Advantages of Complex42™:

- Affordability: It’s a low-cost concentrate used at a dilution of 0.4 to 1%.

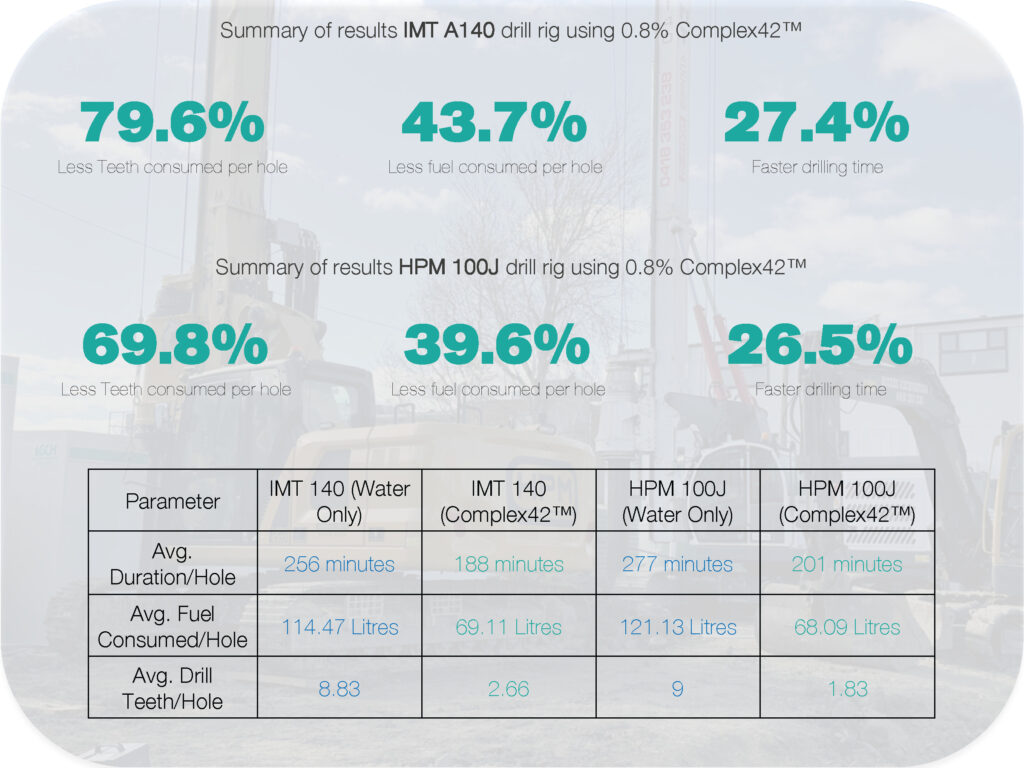

- Enhanced Rate of Penetration (ROP): Real-life ROP improvements of up to 3.4 times have been observed.

- Tool Longevity: The additive preserves tool cutting edges, boosting drill bit life by a staggering 80-90%.

- Operational Efficiency: Reduced wear on the drill string, lubrication of drill components, and minimized machine stress, which in turn extends engine longevity.

- Eco-friendly: Complex42™ is biodegradable, making it an environmentally responsible choice.

Applications of Complex42™:

- Exploration drilling

- Shaft drilling

- Ore milling

- Tunneling and boring

- Wells, geotechnical drilling, and pilings

Understanding the Efficiency and Cost Implications:

Drilling expenses are primarily influenced by ROP and bit life. Complex42™ minimizes drill bit wear across all substrates, leading to notable performance enhancements throughout the entire drilling operation. Additionally, it boosts milling efficiency through the Rehbinder Effect, which softens fresh ore surfaces as it is broken up. This additive can be recycled multiple times with mill water before more additive needs to be introduced to the water supply.

How Complex 42™ Works

- Diamond Preservation: Complex42™ is engineered to minimize diamond wear. Under heat and pressure, it acts as a lubricant and forms a protective layer around the tool. For instance, in a drill string, it has been shown to decrease friction both on the cutting head and the well wall, leading to reduced operational costs.

- Boosted Cutting/Grinding Speed: Leveraging a phenomenon known as the Rehbinder Effect, Complex42™ significantly amplifies cutting and drilling efficiency by softening the rock surface, allowing for increased penetration. The added advantage of diamond preservation means enhanced cutting efficiency throughout the tool’s lifespan as the diamonds remain sharper for an extended period.

Complex42™, with its capacity to significantly enhance drilling efficiency, reduce costs, and contribute to sustainable drilling practices, is poised to redefine the drilling and tunneling industries. By adopting this innovative solution, companies can optimize their operations and usher in a new era of industry advancements.

-

Xcelerate Chemicals Complex42Our Price Starting at From: $2,800.00

Xcelerate Chemicals Complex42Our Price Starting at From: $2,800.00

Have questions about using the Complex42™? Reach out to the pros at Chemical Concepts for expert advice today!