How To Install a Removable Panel: 3 Easy Steps

Fabricators that work with removable panels need an efficient and reliable way to install them. But the processes and hardware you use have a significant impact on the end product. In this post, we break down how to install a removable panel and how to select the right hardware.

Removable panels are widely used across a number of industries, including signage, marine, interior design and public transportation.

While these industries all have unique application requirements, they have one thing in common. By design, removable panels are going to be attached and reattached dozens or even hundreds of times. So, before you begin the installation, it’s crucial to identify hardware and mounting methods that are strong and durable enough to handle repeated installation.

Step #1: Select Your Hardware

When most people think of removable panels, the first thing that comes to mind is the panels themselves. But the signature feature of removable panels – the ability to remove them – comes from what you don’t see: the hardware.

The success of a removable panel feature relies heavily on the strength and quality of the fastening system. So, before you begin installation, it’s worth taking the time to understand the hardware that makes it all possible

Plastic Fasteners

The most common method for mounting removable panels is plastic fasteners. Their low price and high availability has made them the go-to for removable panel installation.

However, it’s worth being mindful of a number of problems you might run into with plastic fasteners.

First, they have low durability and fatigue after prolonged use. The longevity will depend on the product, but plastic fastener will eventually degrade, warp or break after repeated removal of the panel. When this happens, the panels will be difficult to remove or reattach. And there’s a good chance you’ll have to replace all of the hardware.

Second, the plastic fasteners aren’t fireproof. If you have a project that requires fireproof hardware, you can’t use them at all.

Lastly, plastic fasteners are usually an inflexible mounting system. While there are many ways to mount a removable fastener to a panel, manufacturers of plastic mounting systems might offer dozens of varieties — some that use screws, some that can be glued on, etc. If you work with a wide range of materials, you’ll most likely need to purchase, store and transport multiple varieties of fastening systems, which can become a hassle.

Z-Clips

Z-Clips are a type of mounting system that acts like a french cleat, but are made of metal, usually aluminum. Z-Clips can be a good solution for mounting panels but they attach and remove vertically. So, if a technician needs to remove the last panel in the column, they’ll have to remove the entire column, which is time-consuming. It also limits the design of the structure. Vertically removed panels force designers to leave large gaps at the top of an installation that may not be desired to allow room to set the panel and drop it into place.

Stainless Steel Fasteners

To make up for the shortcomings of plastic fasteners, a few manufacturers have introduced metal removable fasteners. Typically made from 301 or 316 stainless steel, metal fasteners make it easier to install a panel in a number of ways.

First, their design makes them extremely durable and provides significant longevity. That’s because a metal part can handle wear-and-tear better than plastic. So, while plastic fastening systems lose force after only three or four panel pulls, metal systems will last hundreds of pulls.

Second, stainless steel is resistant to heat and fire. Unlike plastic, it will not combust or melt. This makes it ideal for areas with fire hazards or projects with strict fire code requirements.

Third, steel fasteners offer better weatherability for outdoor and marine environments. They’ll provide a strong connection even against humidity, salt water, heat, cold and extreme weather.

Lastly metal fasteners, like the Fast-Con from Specialinsert, offer flexibility and the ability to solve problems you otherwise couldn’t.

Suppose, for example, you were working with a thin metal panel and you couldn’t drill a hole in it for the fastener. One way to solve this problem is to use a structural adhesive like UltraLok to attach the female side of the fastener to the panel and use a screw or bolt to mount the male side to the wall.

Price vs. Cost

One final difference fabricators notice between these two mounting systems is price. It is true that steel fastening systems are going to come with a higher price than plastic. The material and design costs of steel hardware make this inevitable.

However, if you’re installing removable panels at any kind of scale, it’s worth considering how your choice of hardware will impact your bottom line beyond the initial purchasing expense.

Plastic hardware can make sense if you have a small number of installations to perform. But if you install a number of them, and pull the panels regularly, the plastic is going to fail and need to be replaced. So, you could end up paying the advertised price of the hardware multiple times.

There’s also the labor costs to consider. Most of the cost of the panel installation doesn’t come from the hardware — It comes from the labor. And a mounting system that’s inefficient and difficult to install is going to create higher labor costs. Plus, there’s the ongoing maintenance and repair costs of replacing failed hardware.

For all of these reasons, panel fabricators are increasingly turning to stainless steel fasteners. The fastening systems may have a higher price upfront, but the durability, labor savings and simplified solution will often reduce your total installation costs in the long run.

Step #2: Define Your Mounting Method

As you can see, there are a number of considerations that go into hardware selection. However, it’s time well spent, as your choice of hardware will have an immediate impact on how you mount the removable panel.

There are a number of mounting methods you can use to install a panel:

● Self-tapping Screws

● Machine screws

● Threaded inserts

● Structural adhesives

● A combination of multiple methods

However, the mounting methods that you can actually use for a panel will depend on what surfaces you are working with. For example self-tapping screws work well for soft materials like MDF or wood. For hard, solid materials like stone, porcelain, plastics and composites you may need a threaded insert like the Keep-nut. You can then mount your removable panel fastener to the insert using a machine screw. For thin materials you can use rivets or you can use an adhesive to bond the faster directly to the surface. You can use these methods in combination if you are joining different materials together.

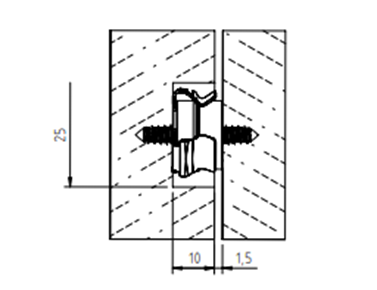

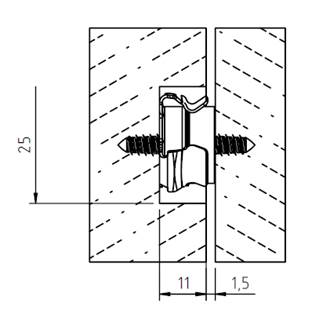

If you are working with soft materials such as wood or MDF, you can choose a surface mount or flush mount installation. For example, the Fast-Con can be recessed into the material by drilling a 1” diameter hole to a depth of ⅜” (10mm) using a spade or forstner bit. This allows you to reduce the gap between the parts.

Step #3: Install Your Panel

Once you’ve done the work of identifying the right hardware, methods and products for mounting the removable panel, the installation step becomes much easier.

If you’re mounting the panel with screws, the process will roughly follow these steps:

● Mark the location on the wall or surface where the fasteners will be located

● Install the female side of the fastener on the marked location using self-tapping screws.

● Set the center point marking tool in the female anchors, line up the panel and apply light pressure on the panel. This will mark the correct location on the panel to ensure alignment.

● Install male side on the panel on the indentations left by the centering device.

● Snap the panel in place

If you’re using an alternative method like structural adhesives or threaded inserts, you can modify this process to follow the products’ recommended steps.

Conclusion

The choice of fastening system has a significant impact on the panels you fabricate. Working with

the right hardware for each application can help fabricators save time and cut costs while improving the quality of their products.

Do you have questions on selecting and using removable mounting systems?

Consult the application specialists at Chemical Concepts!