Keep-Nut Used in Art Project “Confluence”

Reading Time: 4 minutes

Chemical Concepts and our Keep-Nut Inserts made by SpecialInsert were proud to be a part of a new art installation at Rowan University in Camden, New Jersey. This project known as “Confluence” was designed by Michele Gutlove of Design Studio GH out of Natick, Massachusetts. “Confluence” was made to represent the physical convergence of the Delaware and Schuylkill Rivers in comparison to the convergence of the past and and future generations of this areas growing community. With the use of the Keep-Nut Michelle was able to support these beautiful glass panels without the use of bulky fasteners or adhesives.

Michelle first contacted Chemical Concepts in September of 2017 and explained the project to the sales team. Michele’s goal was to find a method of hanging her glass panels into Lueders Limestone. Her need for this was to support these panels virtually invisibly without using rubber, adhesives or any materials that would degrade over time.

The Chemical Concepts Solution: Keep-Nut

Seemingly perfect for this type of application the Keep-Nut has the ability to be installed into numerous types of surfaces including Limestone, Granite, Marble, Quartz, Solid Surface and High Density Concrete. Keep-Nut inserts are made with stainless steel and also require no use of adhesive, essentially ideal for this particular application.

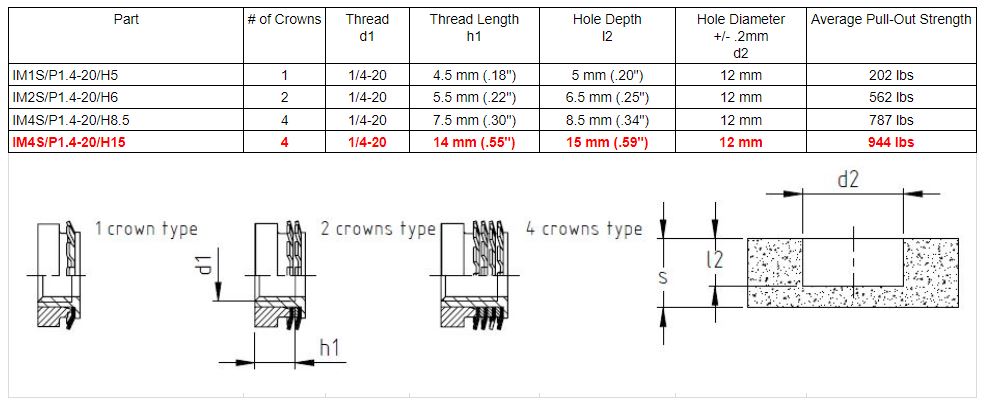

After explaining and sampling various sizes of the Keep-Nut Design Studio GH settled on the strongest Keep-Nut, the IM4S/P1.4-20/H15. This version has 4 crowns (the more crowns the stronger the insert), a 1/4-20 thread, and a 15mm Depth. The reason for this choice was to make sure that each glass piece (although light) would hold over time. As you can see in the chart below this version of the Keep-Nut has the largest average pull-out strength.

Manufacturing and Installation

After testing was approved Michelle and her team then moved forward with the manufacturing and installation of the Glass Pieces. After completion of this process Michelle added:

The Keep-Nuts worked well, and easily. We were installing onsite, so we were using cordless drills. We used a bit to get the correct size hole, and built a jig to ensure the holes were perpendicular to the surface of the stone, and at the correct depth. For the most part the stone was of uniform density, and the drilling went quickly. Of about 230 holes, there were three holes where the stone was more dense, and the drilling was more time consuming. We tested our installation method at my studio with a sample of the stone that was provided by the architect.– Michelle Gutlove of Design Studio GH

Soon after sampling and testing in the studio Michelle and her team then hit the road to Camden, New Jersey for their install shown in the pictures below:

Completed Photos

Installation was soon finished without any issues, see completed photos below. Please feel free to check out more of Michele’s artwork here and contact Chemical Concepts at [email protected] with any questions on how this project was completed with the Keep-Nut inserts.