New Product: Permabond TA4605 & TA4610 Adhesives

The Chemical Concepts team is delighted to announce that we’re now a distributor for Permabond’s brand new TA4650 and TA4610 structural adhesives. These acrylics have been expressly developed to bond polyolefin surfaces, namely polypropylene and polyethylene, without the hassle and cost associated with surface pre-treatment.

Bonding Polyolefins

Polyolefins are thermoplastic materials, like Polypropylene and Polyethylene, that are often used in a range of industries to wrap, insulate and conform. Polypropylene is used with packaging, labeling, plastic parts, automotive components, and some textiles and carpet, while Polyethylene, which is the most common type of plastic, is used in making plastic bags, bottles, containers, etc.

These types of Polyolefins generally do not adhere well without rigorous surface treatment because of their extremely low surface energy. That’s why Permabond’s TA4605 and TA4610 toughened acrylic adhesives are so revolutionary – they bond Polyolefins without the need to prime or painstakingly prepare the surface. A simple cleaning of the surface to remove any wetness or grease is all that’s necessary for a relatively fast curing process and a lasting and strong bond!

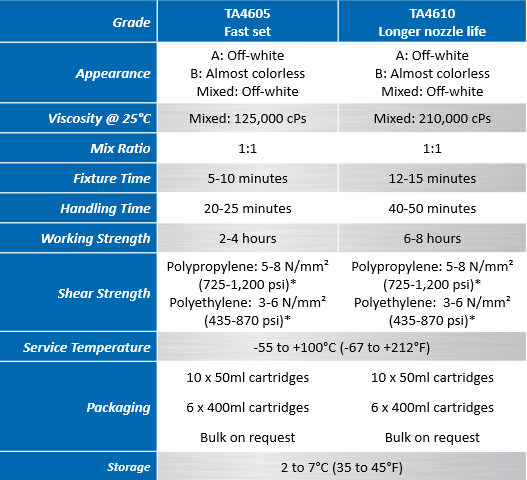

The TA4605 &TA4610

These innovative methacrylates from Permabond make the bonding of Polyolefins much more convenient and cost effective. Having the ability to bond Polyolfeins to a variety of substrates, these two-part acrylics have a fixture time of 5-10 minutes (TA4605) or 12-15 minutes (TA4610), respectively. They also have the ability to cure at room temperature and come in easy-to-use 50 ml and 400 ml cartridges. If you’re interested in a slower curing product, the TA4620 grade is available upon request.

The application process is simple, involving only five easy to manage steps:

1. Clear your surface of any moisture or grease

2. Apply a thin bead of pre-mixed adhesive through the static mixer nozzle

3. Assemble components and clamp

4. Maintain pressure until handling strength is achieved. This will depend on joint design and surface, but full strength can typically be reached in about 20 hours at 23 degrees Celsius.

5. Allow 24 hours for full cure

Features

- Adheres to a wide variety of substrates

- No primer or tedious pre-treatment is required

- Good chemical resistance

- Good impact strength

- Cures fully at room temperature

- Effective at bonding dissimilar surfaces

- Easy 1:1 mixing ratio

- Can easily be applied either manually or with the help of an automatic dispensing gun

- Non-Hazardous and easy to transport

Permabond at a glance

Permabond is one of the world’s leaders in adhesives, sealants, structural acrylics, epoxies, and the like. Chemical Concepts has been a trusted supplier of Permabond’s performance adhesive products for some time, carrying an extensive line of its products. Their adhesive products are distributed and used by customers in just about every industry, from construction to electronics.

Are you unsure about your application? Fill out our straightforward ‘Discuss Your Application’ form and get specific answers from knowledgeable representatives. Simply answer the provided questions by selecting the proper drop-down field or writing a detailed description of your dilemma, and an adhesives expert will be in touch with the answers!

Contact our sales team today – [email protected] – 800.220.1966