Description

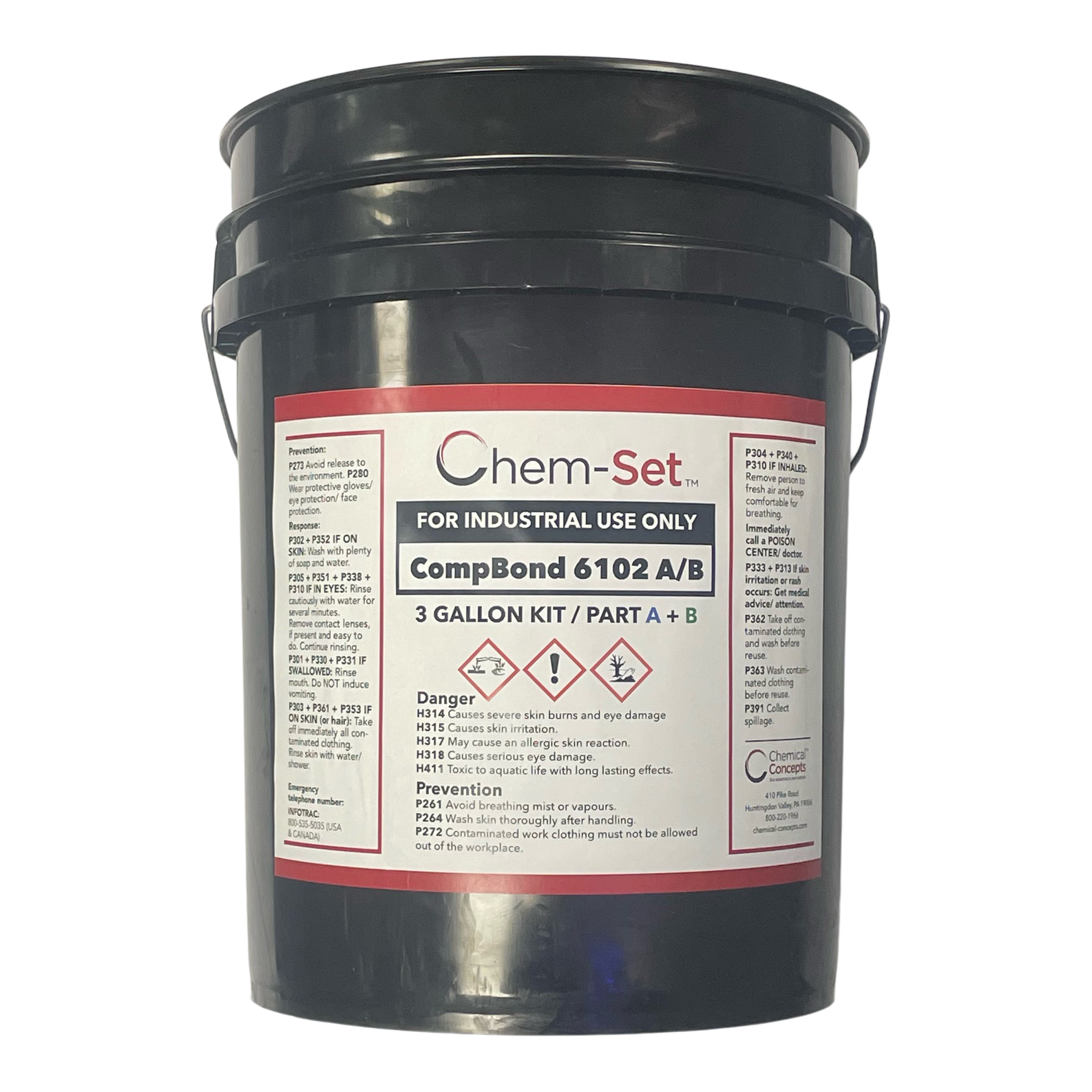

CompBond 6102 is a high-performance Epoxy for Panel Bonding & Lamination

Achieve superior strength, thermal resistance, and long-lasting durability for demanding applications.

Key Features:

- Strong & Durable: Delivers exceptional performance, thermal cycling resistance, and aging resistance for panel bonding.

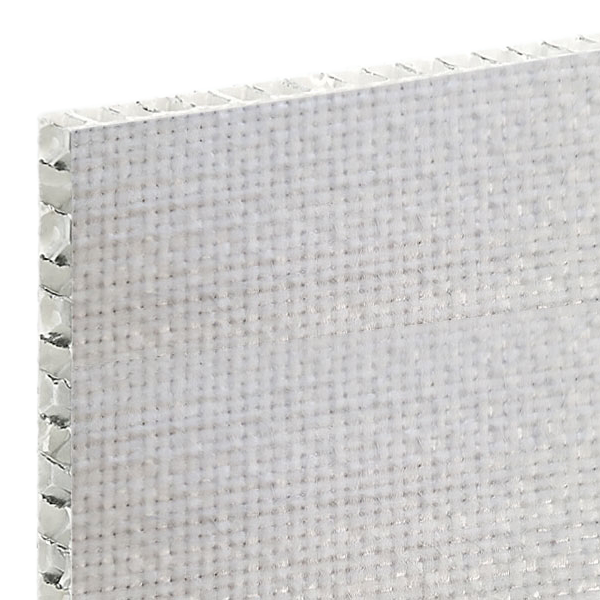

- Versatile: Bonds a wide range of materials, including metals, aluminum honeycomb, ceramics, and more.

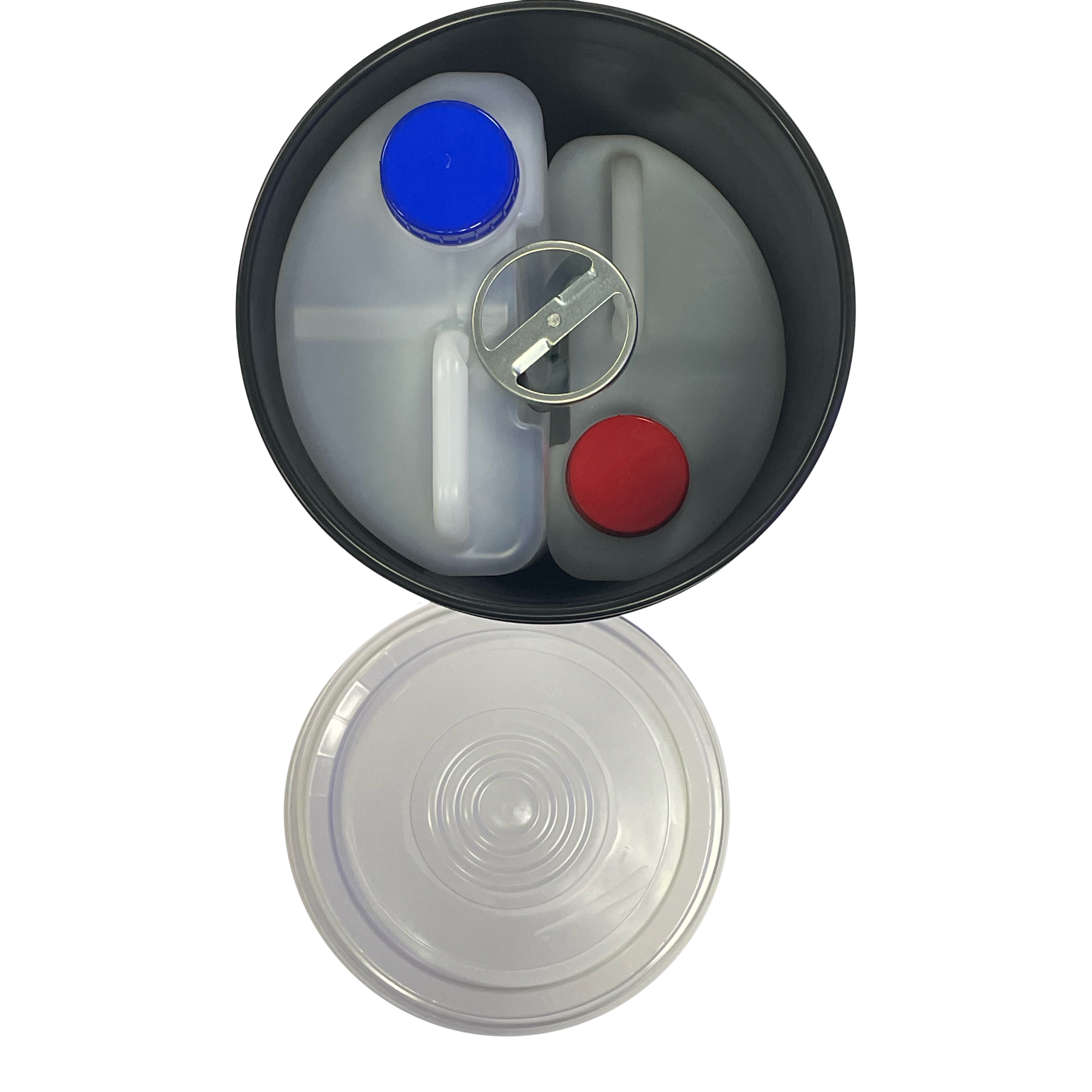

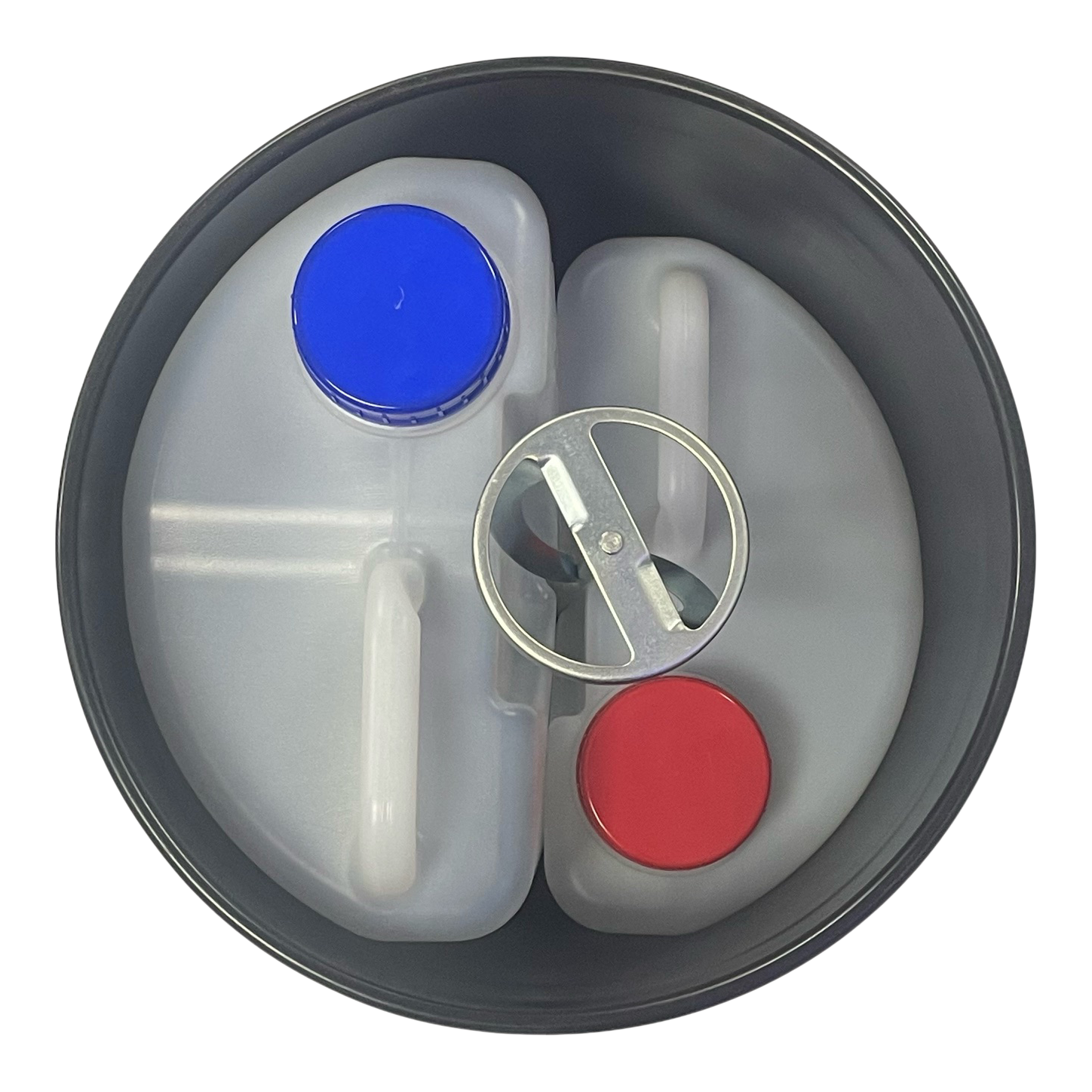

- Convenient Packaging: Pre-packaged in easy 2:1 mix ratio containers with a mixer

- Easy to Use: Features a convenient 2:1 mix ratio, lower viscosity for smoother application, and long work life.

- Cost-Effective: Reduces material costs with lower viscosity and minimal shrinkage.

- Fire Safety: Meets flame, smoke, and toxicity requirements for passenger rail applications

Benefits:

- Fast Curing: Saves time with a short curing time at room temperature.

- Effortless Application: Easy to mix and apply for efficient use.

- Superior Strength: Delivers excellent mechanical properties for reliable bonding.

- Exceptional Resistance: Withstands harsh environments with outstanding thermal cycling and damp heat resistance.

- Preferred Failure Mode: Promotes cohesive failure within the adhesive layer for a clean separation.

- High Peel Strength: Ensures strong adhesion for long-lasting results.

Applications:

- Honeycomb Panel Lamination

- Stone Panel Lamination

- Architectural Cladding

- Facade Panels

- Transportation (Railway, Bus, Truck & Trailer)

- Architectural Panels

- Cold Rooms

- And More!

Specifications:

- Pot Life: 80 mins @ Room Temperature

- Fixture Time: 8-9 hrs @ Room Temperature

- Color: Tan

- Mix Ratio: 2 Parts Resin to 1 Part Hardener

CompBond 6102 vs. Competitors:

- CompBond 6102 outperforms competitive adhesive even at a thinner bond line thickness

- The lower viscosity of Araldite 9102 helps to ensure even and full coverage across the entire surface area

- The thick consistency of competing products results in peaks/valleys under the material, the only way to truly eliminate that would be to add additional clamp pressure over the bonded surface

- CompBond 6102 showed no samples with delamination after testing

- Meets flame, smoke, and toxicity requirements for passenger rail

- Improved performance

- Cost savings/process improvements

Instructions for Panel Lamination:

- Use the coverage chart to estimate the amount of resin and hardener needed. Resin and hardener should be mixed at a ratio of 2:1 by volume

- Pour into outside mixing bucket packaging

- Note: If using less than the full volume use a graduated beaker to measure the desired volume (2 parts Resin to 1 part Hardener). Use a dedicated beaker for resin and a dedicated beaker for hardener to avoid cross-contamination

- Use the provided mixer or paddle to gently mix the materials until the product looks uniform with no streaking. Make sure to scrape the sides of the container during mixing

- Pour the desired amount on the honeycomb side and use a 1/16″ or 1/32″ notched trowel to spread the material on the workpiece. Try to put the notches in straight lines in 1 direction. Remove excess.

- Apply the porcelain/stone panel material on top of the honeycomb panel and clamp in place. Use a vibrational tool on the surface to improve contact and smooth out ridges in the adhesive. Apply weights and tighten clamps to reduce/eliminate gaps between the porcelain and the honeycomb

- The adhesive has an 80-minute working time at 70° F. You should be able to move the parts after 2-3 hours at 70° F. Full cure is 24 hours. The product may feel tacky at 2-3 hours but it has achieved some handling strength sufficient to move the parts and prep for the next fabrication steps

- Clean the trowel and any reusable tools with acetone while the adhesive is still wet

- For best results, keep the work area and work surfaces as close to room temperature as possible

Reviews

There are no reviews yet.