Rapid Prototype Mold Making: 5 Ways to Make Your Process More Efficient

Silicone compounds have transformed the rapid prototyping process, adding greater cost savings and flexibility vs. metal molds. In this post, we break down five ways prototype fabricators can save money by making their processes more efficient.

Increase Parts Per Mold

Every mold has a limited shelf life. And the number of times you can use a mold has a significant effect on costs. One way prototype fabricators can improve their margins is by using molding materials with greater durability and longevity.

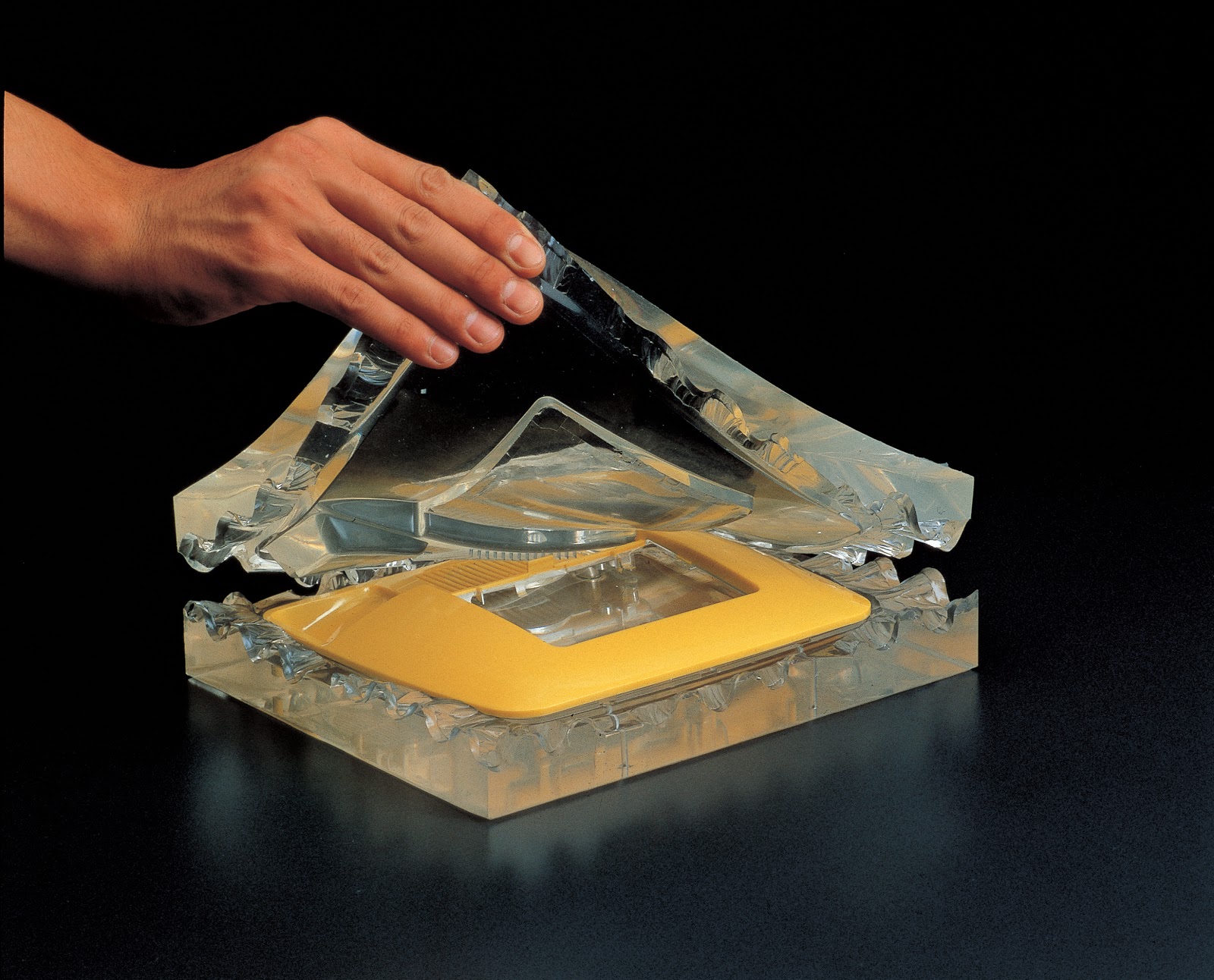

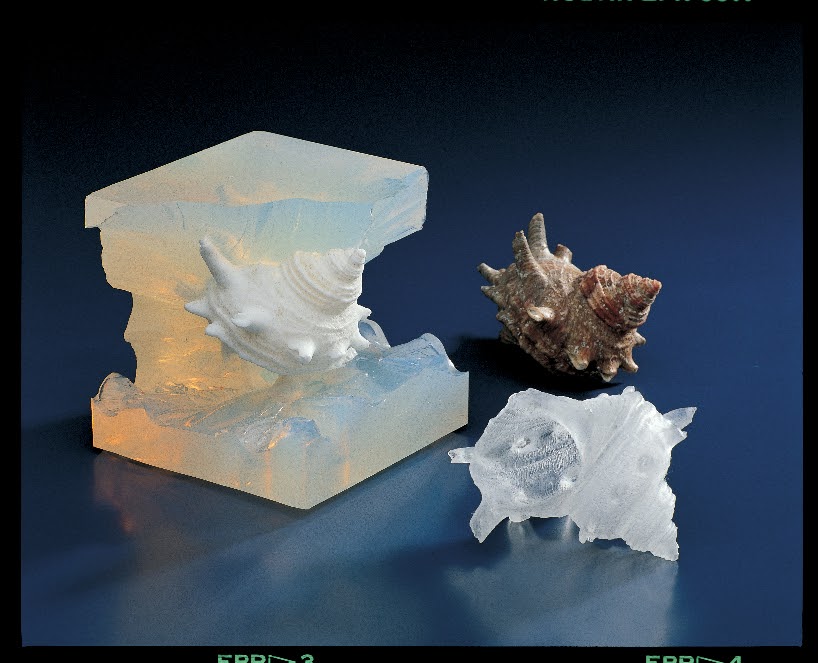

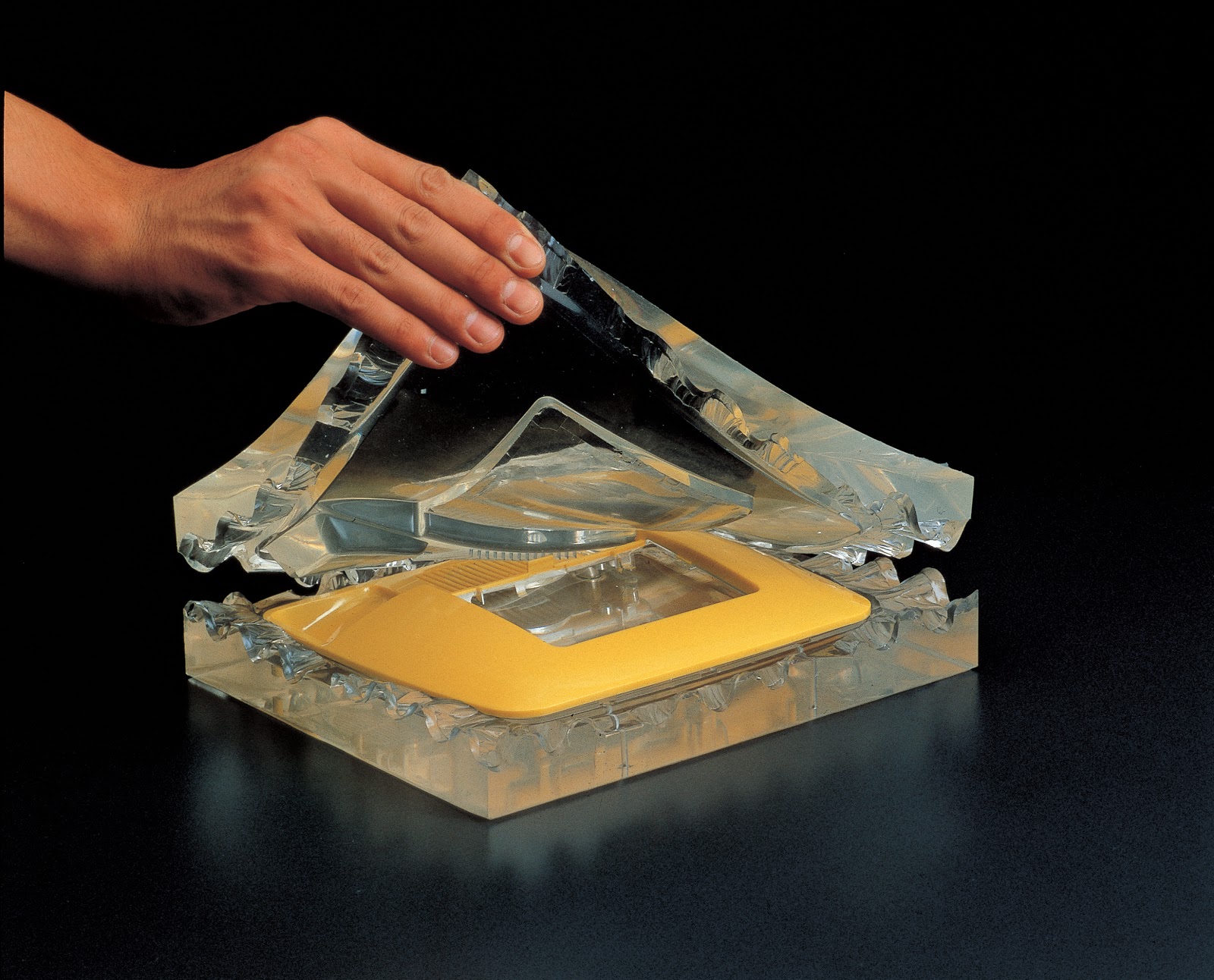

Silicone molding offers great temperature resistance that stands up to the extreme heat urethane casting materials produce as they cure. They also provide resistance to tearing that allows you to pull your parts from the mold more times without damage.

With these features, higher quality molds allow you to get much more mileage out of each mold. This reduces the total amount of material you use, resulting in significant savings. Case in point, users of the Shin-Etsu SES22251 silicone are reporting 10-20% improvements in parts per mold.

Use a Low Density Silicone

The strategy most businesses use to reduce material costs is to look for products with a lower price. But the silicone molding industry is a competitive space. Most of the technology hasn’t changed in 10 years, and the price differences between products are fairly small.

Fortunately, there is a way for prototype fabricators to reduce material expenses: use a lower density product.

Because pricing is often based on weight, a low density silicone provides significantly more volume for the same cost. With some low density formulations of silicone molding product, you can see as much as 20% more volume of silicone per lb compared to standard products. That additional volume leads to a 20% decrease to your molding material costs across the board.

Use a Lower Viscosity

The easiest way to optimize your molding process is to speed it up. A low viscosity silicone will pour much faster than a standard compound. This enables you to get the liquid silicone rubber in place faster, which can save you a lot of otherwise wasted time.

In addition to reducing labor costs and speeding up the process, lower viscosity compounds also offer material savings. A low viscosity product de-airs more quickly, reducing the chance for unwanted bubbles that can ruin the mold. This creates less material consumption and waste.

Would you like to discuss available options to optimize your mold making process?

Consult the application specialists at Chemical Concepts!