Static Mixer Shortage: 5 Factors for Finding the Right Substitute

Recent supply chain issues have made static mixers harder to find. The good news is there are plenty of viable substitutes. In this blog, we’ll tell you what to look for and how to find the right static mixer replacement.

There’s a perfect storm brewing in the world of static mixers and dispensing equipment. And it involves two major manufacturing plants – one that’s struggling to ramp up production after moving, and another that’s shut down.

These events have created an unprecedented production crisis for static mixers. If you’re not already feeling the effects, it may soon become much harder to find the dispensing equipment you rely on for your business.

To better prepare you for this shortage, we wanted to give you an overview of static mixers as well as some tips for finding a replacement for the models you normally use.

Static Mixers – A Basic Overview

Before we explain how to find a substitute for your mixers, let’s discuss what these mixers are and some of their basic parts.

What Are Static Mixers?

Static mixers are disposable attachments used for mixing and dispensing two-part adhesives from cartridges or meter mix systems.

Static Mixer Characteristics

Two-part adhesives have a variety of formulations that lead to a range of viscosities and other physical characteristics, for a variety of applications. While static mixers share many basic characteristics, some important differences exist.

#1. Dimensions – Length and Diameter

Static mixers come in a wide variety of lengths and diameters. With longer mixers, the adhesive is run through more mixing elements ensuring a more thorough mix. Longer mixers also allow you to reach tighter corners to apply the adhesive. The drawback is there will be more adhesive left in the mixer as waste.

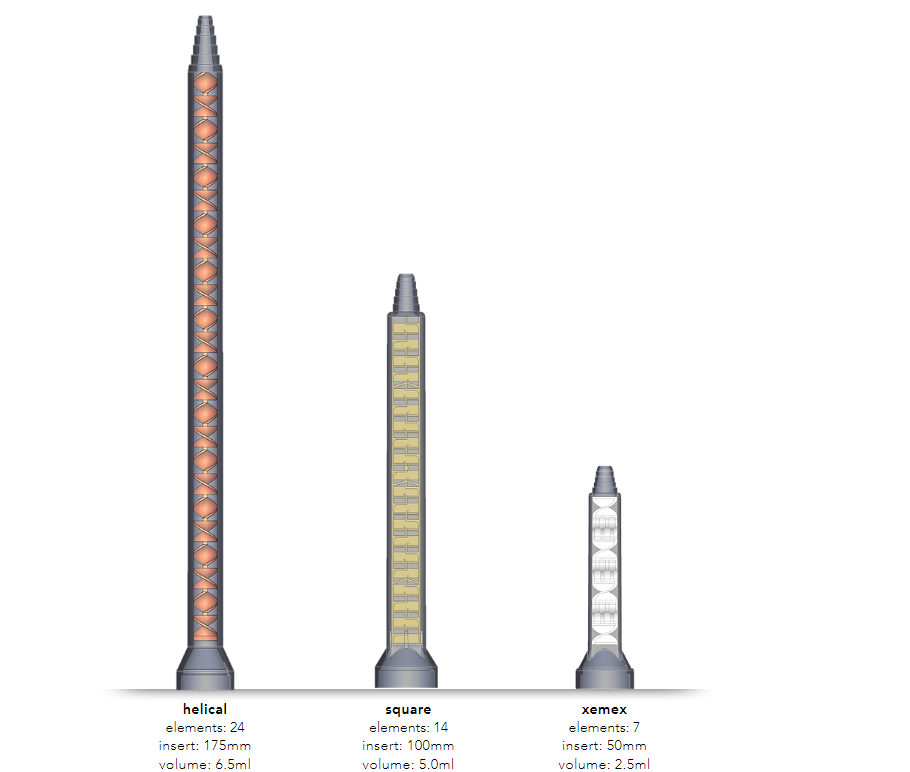

#2. Mixing Elements – Number and Type

Mixing elements are the number of sections that fold and mix the adhesive as it travels through the mixer. There are two general mixing element shapes – helical and square, both with their own mixing properties.

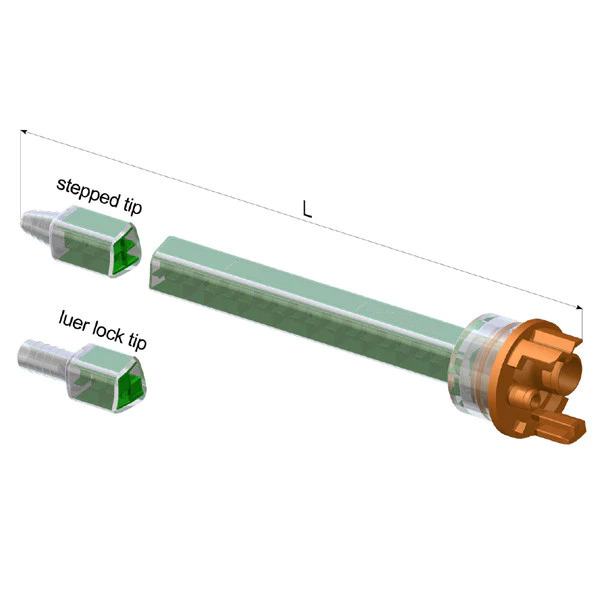

#3. Attachments and Connections

Every static mixer has some form of inlet attachment point and an outlet or tip. The inlet attaches to your cartridge or meter mix system. The outlet is the hole that the adhesive gets dispensed through and there are different options to connect to needle tips and different accessories. Inlets and outlets differ depending on the system you’re using and the size of bead that you want to dispense.

Finding a Static Mixer Substitute – 5 Features to Look At

Now that we’ve covered the basics, let’s look at how to find a replacement for your mixer.

Mixers share many similarities. If you can find one that attaches to your dispenser and only has a few slight variations, you’re probably good to go.

In some cases you will find a mixer that works with no change in performance. Other times you may have to make some compromises if you are unable to get your hands on the ideal mixer for your process. But when your choices are between using a less-optimal static mixer and halting production, you’ll take the less-optimal mixer every time.

Here’s what to consider when choosing a replacement.

#1 The Brand

There are numerous static mixer brands out there, including Medmix and Nordson – two of the most popular.

When searching for a replacement, often the easiest thing to do is to look for a similar or identical mixer from another brand. Some mixer manufacturers have some proprietary designs, but many popular mixers are somewhat standard with comparable offerings available from several of the major brands.

For example, if your standard mixer is the Nordson 190 620, you can try using a Medmix MAH 06-21T

#2 Mixing Elements

Like we mentioned, there are two main types of mixing elements – helical and square.

The helical mixing elements are the traditional design and do a good job of mixing the adhesive. But square shaped elements have become more popular because they can efficiently mix the adhesive using fewer elements. That means less waste.

Going from helical to square is easy and allows you to use a shorter mixer. But if you’re going from square to helical, you may need a longer mixer to achieve the mix quality you’re used to.

If you can’t find an identical mixer for your application, try looking for a square version if you are using a helical mixer or vise versa.

For example if you use a Medmix MCH 08-24T you could try the MCQ 08-24T instead.

#3 The Inlet

There are a few common inlet types that most static mixers use to attach to the cartridge or dispensing equipment. These don’t include proprietary systems, which we’ll cover in a later section.

For mixers that use generic inlets, make sure your replacement uses an inlet that is compatible with your cartridge or meter mix system. The three most common types are bell housings, integral nuts, and bayonet mixers.

- Bell housing mixers – These connectors are the most traditional and are commonly used with 200ml, 400ml & 600ml cartridges. All major manufacturers make them. You connect the mixer to the adhesive cartridge and a retaining nut slips over the top to hold the system together.

- Integral nut – These are also very cross-compatible. An integral nut connection is when the inlet end of the mixer itself is threaded and able to screw on to the adhesive without a retaining nut. These one-piece connections are a little more convenient than the traditional bell housing. Bell housing and integral nut mixers are also interchangeable on most cartridges and dispensing systems.

- Bayonet mixers – These mixers are traditionally used on smaller cartridges. They are a rectangular connection that clips onto the adhesive with a quarter turn. These are not interchangeable with the other connections.

This is another easy substitution. If your mixer has a bell inlet, look for a similar mixer with an integral nut. For example if you use a Nordson 180A 824 you can replace that with a 180AN 824. This is an identical mixer with a retaining nut instead of a bell.

#4 The Outlet

You’ll want to make sure the replacement mixer you choose has a similar outlet tip to the one you normally use.

The good news here is, a lot of mixers come with a stepped tip. These allow you to choose the bead size you want by cutting the tip to the size you need.

If you use a specialty attachment such as a ribbon tip or a needle tip, you’ll want to make sure that your replacement can accept it.

If you need a specific mixer with a stepped tip, you can look for a similar mixer with a luer lock tip, slip luer or barbed tip. For example, users of the TAH 190-620 mixer can also use the TAH 190-620LL which is the same except it has a luer lock contention on the end.

#5 The Dimensions

Look for a replacement with a similar diameter and number of mixing elements.

The diameter of a static mixer plays a huge role in how much back pressure there is coming through the cartridge or meter mix system. If you have a thick adhesive, it will be much harder to use a static mixer with a diameter that’s thinner than what you normally use.

With the length, going from a shorter mixer to a longer mixer will usually work. The longer the mixer, the more mixing elements your adhesive passes through, so your mix quality won’t degrade with a longer mixer. However, you will waste more adhesive with each mixer you use. That said, it’s still better than halting production.

For example users of the TAH 180A 818 mixer can also use the TAH 180A 824

#6 Proprietary Systems

The last thing to consider is any proprietary systems that your normal mixer uses. In general, if you’re using a mixer that uses a patented, proprietary connection, you’ll need to find a replacement with that same system.

Some popular proprietary systems are the F-Style and the B-Style from Sulzer. Nordson has an attachment that gets around the F-Style system, so that’s a possibility if you’re an F-System user. This allows you to use any bell or integral nut mixer on your cartridge.

For example, If you use the MFQX 08-24T you can use the Nordson 7362809 as a drop in replacement.

Ritter also has their ACF system, but it’s a little less popular in the US. Finally, Integra has their own system but it offers no cross-compatibility. Integra mixers only fit on Integra adhesives.

New Technology

Above, we advised to look for a mixer with a similar length and number of elements. One notable exception to this guideline would be the Xemex series mixers from Remixer.

These innovative mixers use new mixing technology to achieve much more efficient mixing in a much smaller package. This allows you to replace a 24 element mixer with a much smaller 7 element nozzle, with no reduction in quality or performance. Because these mixers are shorter, that gets you closer to the workpiece and results in savings of around 75% in retained volume. Depending on the cost of your adhesive, this could save you $.70-$1.00 per mixer in waste!

Someone using the MCH 08-24T could use the X2-B8-7S and put all those savings right back to the bottom line.

Conclusion – Chemical Concepts Can Help

Hopefully, you’re well on your way to finding usable substitutes for currently hard-to-find static mixer models. If you still have questions, feel free to reach out to our adhesive experts. Chemical Concepts has been a leader in adhesives and the systems used to dispense them for decades. We can help you find the right static mixer substitute for your business needs.