Structural Adhesives: 3 Benefits Over Traditional Assembly Methods

Demand for structural adhesives has skyrocketed—even in industries that would have never considered alternative assembly methods in the past. In this post, we discuss the benefits of adhesives and how they are positioned to replace two common assembly methods.

Structural adhesives are “load-bearing” adhesives that are used to bond a joint and hold two (or more) substrates together under stress, suitable for a vast majority of composites, thermoplastics, metals, and dissimilar substrates. The results are clean, durable bonds capable of withstanding the harshest climatic conditions with minimal surface preparation.

Here are the top three benefits of adhesives.

3 Benefits of Structural Adhesives

#1. Light Weighting & Gauge Optimization

First, adhesives bond across a continuous, even area, distributing stress across the surface of the material as opposed to concentrating stress at certain points. This even distribution of stress (and lack of heat distortion or holes from traditional assembly methods) means there are less failure points of the structure, improving overall durability.

Other methods of fastening require thicker materials to achieve the same performance that adhesives can produce. Because of this, you can light weight and downgauge your materials and still maintain the same necessary strength. In fact, adhesives allow up to 37% lower mass of assembly. You can then ship, move and create the product with less energy and resources. This brings us to the next benefit.

#2. Time & Labor Savings

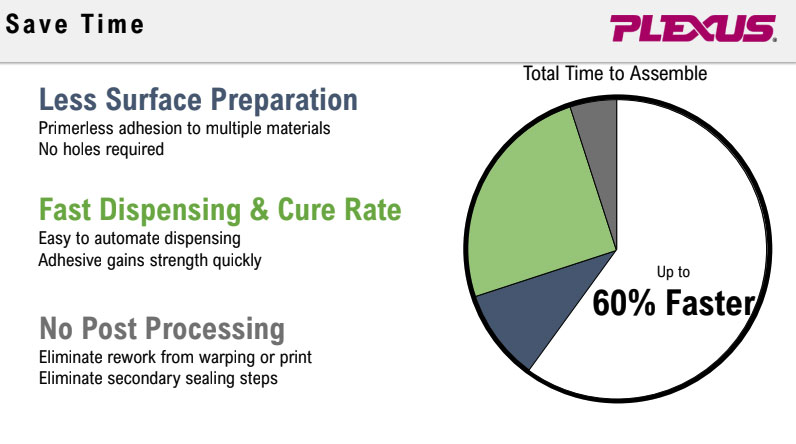

Structural adhesives save manufacturers time and money in a number of ways.

First, it reduces the number of manufacturing steps required, speeding up time to assemble by up to 60%. This is because adhesives require less surface preparation, have a fast dispensing and cure rate and don’t require post processing.

From a cost perspective, adhesives can reduce total cost of assembly by up to 50%. They don’t require specialized labor (so, lower pay requirements) and, compared to other assembly methods, have a low associated equipment cost. Also, strength to surface area per dollar spent ratio is higher (i.e., more cost-effective) due to simplified manufacturing and reduced inventory.

#3. Bond Dissimilar Materials

Today’s products use a wide variety of materials. But bonding dissimilar materials is a challenge due to the varying chemical properties of different substrates.

For example, polymer materials are popular in automotive applications because of their low weight, high strength and low cost. But how do you bond a polymer to metal components?

Structural adhesives are the answer. They can bond dissimilar substrates quickly and effectively with minimal surface preparation. This allows for more design freedom without adding to production time or sacrificing durability.

Considering Adhesives to Replace Traditional Assembly Methods

To see these benefits in action, let’s compare two traditional assembly methods to structural adhesives.

1. Welding

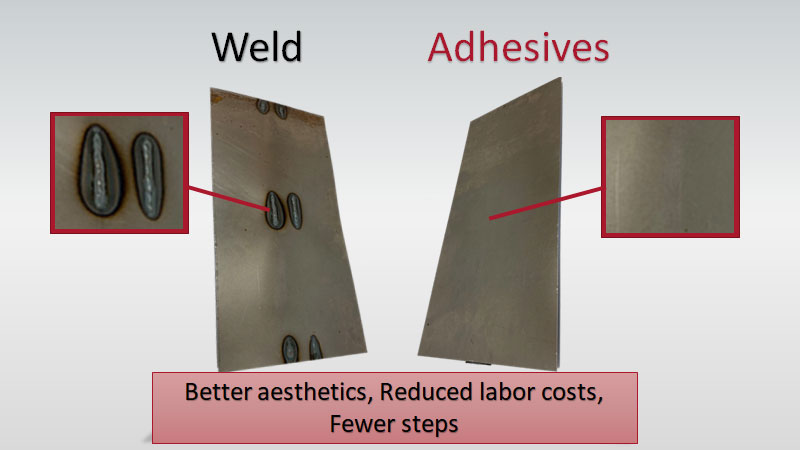

Welding is a highly specialized field, which means there’s a limited supply of skilled labor and higher pay requirements. Not to mention, it can be hard to find a skilled welder, which means many end up settling for subpar labor instead.

Also, most assume welding is strong. But the welding process can actually lead to heat distortion, which weakens the strength of the joint and sheet metal. Heat-affected zones can lose up to 40% of strength! This means you have to go for a higher gauge and strength to compensate.

Finally, cleaning up the weld takes more time. With adhesives, you simply wipe off the excess and let the bond dry and cure. In addition to the three benefits discussed earlier, adhesives create a smooth, clean edge that looks better than most weld jobs.

2. Rivets

2. Rivets

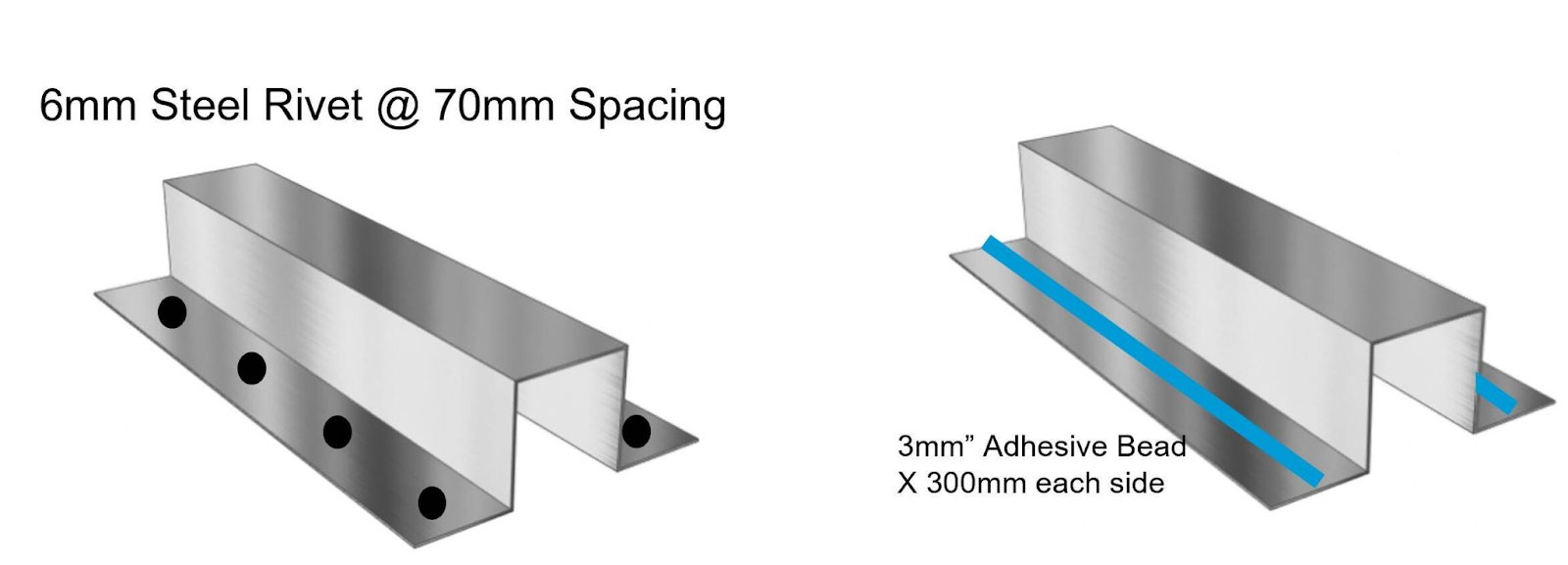

Rivets concentrate stress in specific points where the structure is joined. As covered earlier, that can weaken the bond at the rivet point and eventually compromise the structure as well.

From a process and labor perspective, riveting is more expensive, requiring more materials, tools and time. And the repetitive motions and ambient sounds create ergonomic and safety issues for workers.

Adhesives solve these problems and more. Especially the right type of adhesive, which can handle galvanized materials containing zinc. Some adhesives tend to struggle with bonding materials like that—leaving riveting as the only option—but there are products designed specifically for this application.

By these comparisons, it’s clear that structural adhesives are a great opportunity for manufacturers looking to replace traditional assembly methods. But to know for sure, conduct a cost study and reach out to your adhesive supplier who should be able to help you put this together.

Cost Study: Structural Adhesives or Traditional Assembly?

If you’re looking for a way to streamline processes and save money, consider replacing traditional assembly methods with adhesives. Like many materials today, adhesive costs are rising, but metal costs are rising even higher. Downgauging can help protect you from rising material costs that eat away at your profit margins. Using the right process for each application can help you reduce expenses while improving your manufacturing process.

So, conduct a cost study to see what works best for your organization. Here’s what to include:

- Cycle time

- Expenses

- Labor costs

- Opportunity costs of time spent manufacturing

- Material costs & savings

- Equipment costs and capital expenditures

It’s important that you have an accurate measure of your assembly costs as you decide.

Need help with your cost analysis or deciding on the right product for your bonding application? Chemical Concepts can help. We are also proud to stock ITW’s line of Plexus products, advanced structural adhesives that improve manufacturing and assembly techniques and processes.

For help finding the right product, contact us today. We look forward to hearing from you!