Tesa’s ACXplus – The Constructive Bonding Application Forerunner (Part I)

Reading Time: 3 minutes

The ACXplus line of adhesives, from industry leader Tesa, is the self-proclaimed “high performer” of the bunch as it relates to Tesa’s roster of effective and relatively high performing tapes. The fact that it’s atop Tesa’s list, along with multitudes of other quality and trusted tapes speaks volumes, and it is reason enough to focus attention on the ACXPlus products in today’s blog.

For starters, ACXplus was created and formatted for the sole purpose of constructive bonding, as opposed to signage, furniture, cladding and facades, or other purposes for industrial tape. The ACXplus line of double-sided, acrylic tapes are characterized mainly be three advantages that truly set them apart. They are:

- BONDING POWER

- STRESS DISSIPATION

- WEATHER RESISTANCE

Bonding Power – To achieve a powerful and enduring bond, even on dissimilar or rough surfaces, several things come into play that ACXplus offer beautifully. The first is chemical – The acrylic makeup of ACXplus tapes allow them to secure optimal wetting and, in turn, will chemically adapt to the surfaces with which they’re bonded. Second, tape thickness can be adjusted to account for surfaces not uniform or surfaces that are coarse and difficult to bond. However, with the ability to adjust tape thickness, a strong and total seal can be achieved, resulting in a bond that lasts.

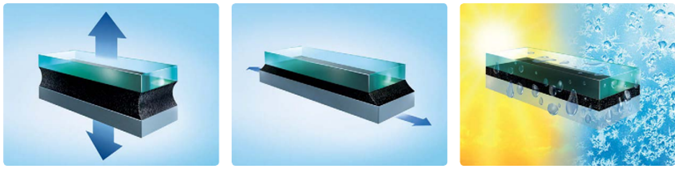

Stress Dissipation – It’s inevitable that over time a bond will face the challenges of both static and dynamic stress. ACXplus tapes have outstanding viscoelastic properties, which means that stresses that can and will arise are dissipated. Even in extreme temperature scenarios, joint partners bonded with ACXplus tapes can usually withstand the pressure.

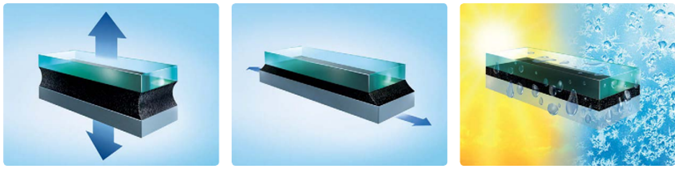

Temperature & Weather Resistance – Bonds can easily fall prey to temperature, weather, UV hazards and the influence of chemicals. ACXplus tapes, on the other hand, are able to resist these factors for a couple of reasons. Firstly, the chemistry that occurs during the curing process creates a network that simply resists weather, even the extremes. Secondly, the makeup of these acrylic tapes is typified by excellent oxidation resistance of its fully saturated carbon ingredients. This means essentially that extreme elements or outside threats can easily be repelled, maintaining a formidable bond for a long time.

Where should I use ACXplus tape?

There are three principal applications for the ACXplus line of constructive bonding tapes. They are:

- Bonding transparent and translucent materials

- Bonding hard-to-bond materials

- Bonding panels and reinforcement bars

ACXplus tapes do not suit these three processes exclusively but they are specifically designed for high performance in these areas. Not only do these tapes replace the tedious and time consuming variables that follow bolting, riveting, welding, or liquid gluing, they actually tend to outperform them as well.

What to look forward to in Part II

Next week we’ll actually dig into individual ACXplus products and their specialties and technical features. This should help construction professionals distinguish and choose the right ACXplus tape for their application.

For more info in the meantime, don’t hesitate to reach out to our customer service team!

[email protected] – 800.220.1966