Two Marine Adhesives That Our Customers Love

Sunny days relaxing on the dock or skimming over the waters in the boat can be the stuff of dreams. But practical needs like adhesives that work well in wet environments and in high humidity are the real tools that can help those pleasant dreams become reality. Let’s highlight two products that we are quick to recommend to customers who are seeking help with marine adhesives.

Sikaflex 295 UV resistant Adhesive/Sealant (300 ml cartridge)

Sikaflex®-295 UV is a fast curing, UV resistant, one-component, flexible, high performance polyurethane-based adhesive that bonds and seals in one step. Some of its more popular uses include bonding and sealing of windows and portholes, sealing wooden boat decks, repairing slate borders around swimming pools, and general marine sealing. It’s formulated for use as an adhesive and/or sealant in bonding applications for polycarbonate windows and acrylic (PMMA) windows. We’ve also gotten reports of clients successfully using Sikaflex 295m to adhere and seal polycarbonate to untreated wood in a greenhouse.

Sikaflex®-295 UV is a fast curing, UV resistant, one-component, flexible, high performance polyurethane-based adhesive that bonds and seals in one step. Some of its more popular uses include bonding and sealing of windows and portholes, sealing wooden boat decks, repairing slate borders around swimming pools, and general marine sealing. It’s formulated for use as an adhesive and/or sealant in bonding applications for polycarbonate windows and acrylic (PMMA) windows. We’ve also gotten reports of clients successfully using Sikaflex 295m to adhere and seal polycarbonate to untreated wood in a greenhouse.

Sikaflex 295 is UV resistant, color-stable, and non-chalking. This is an application that calls for a UV-resistant adhesive with a high degree of elasticity. Sikaflex-295 UV combines the necessary elasticity with just the right consistency to maintain the required bond line thickness. This helps to ensure that thermal movements in plastic glazing panels are progressively absorbed and avoid an undue build-up of stress.

In order to help you blend colors well in your marine adhesive needs, Sikaflex 295 is available in black or white.

Here’s a quick look at some additional features of this multi-purpose product:

- Low VOC.

- No added solvents.

- Excellent UV and weathering resistance.

- Suitable for organic glass like PC or PMMA.

- OEM approved.

- Easy workability.

- Resistant to both salt water and fresh water.

- Silicone free.

- Wheelmark certified.

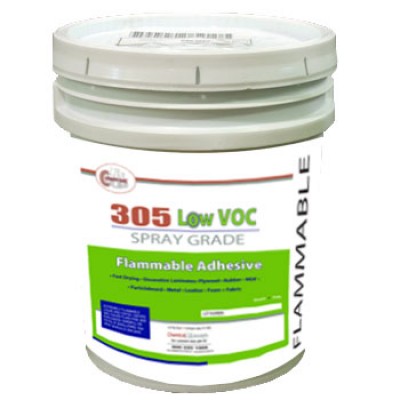

Chem-Set 305 Low VOC

Chem-Set 305 is a flammable high solids synthetic elastomer contact bond adhesive specifically formulated for bonding various types of polystyrene foams and plastic laminates to plywood and aluminum skins. Our customers give us great reports as they use this with recreational vehicles, mobile homes, modular panels , as well as for the installation of carpeting for boats and pool decking.

Let’s explore a few of the Chem-Set 305 advantages:

Let’s explore a few of the Chem-Set 305 advantages:

- Excellent spray break up and fluid distribution rates, which will not attack foam.

- High resistance to water, humidity and alcohol.

- Allows immediate machining – after at least 20 psi of pressure between the two substrates to be bonded.

- High heat, creep and dead load resistance.

A few hints for usage:

- Substrates should be under at least 20 psi or more if available within the limitations of the substrate.

- Adhesive coat should be dry (normally 2-5 mins. dry time is sufficient).

- Cure: 90% within 12 hours and full strength within 2-3 days.

In order to help you blend colors well in your marine adhesive needs, Chem-Set 305 is available in red or clear.

If you’re repairing and maintaining your boat or your dock, or generally using materials around water and high humidity, we encourage you to check out these products for your adhesive needs. Our sales team is happy to make suggestions and answer any questions that you might have. Call us toll-free at 800-220-1966 or email us at [email protected].

We’re happy to help you toward smooth sailing!