Welder Shortage: Keeping Projects Moving Without Skilled Labor

It’s well known that there has been a welder shortage for some time now. And the post-pandemic labor market is only making those problems worse. Here’s how you can keep projects going when welders (and all skilled laborers) are hard to find.

According to the American Welding Society (AWS), by most estimates, the US welder labor market will reach a deficit of 375,000 workers by 2026.

Finding skilled labor has always been difficult, but today where all industries are facing labor shortages, the welding labor market has really been hit hard and will continue to be hit hard well into the future.

This means if you rely on welders in your production lines, you’re probably scrambling to hire welders or retain the ones you have. But the truth is you have other options.

Adhesives can help you reduce (and in some cases, eliminate) welding in your manufacturing process. In these next sections, we’ll go over some of the benefits of adhesives, the drawbacks of welding, and how to overcome the welding shortage by making the switch to adhesives.

The Benefits of Adhesives

You might be thinking – “Really? Adhesives? Instead of welding?”

That’s common, especially if your notion of adhesives is a few decades old. But the adhesives of today are nothing like the adhesives of yesterday. You can bond just about any substrate, quickly and with more than enough hold strength to meet any industry specs.

Here are some of the benefits adhesives offer compared to welding.

#1) Lower Assembly Costs

With adhesive solutions, you may see some cost increases in materials. But don’t let that increased cost get in the way of making the switch. The money you’ll save in hiring and retaining skilled welders will completely outweigh the slight increase in materials costs.

Don’t be penny-wise and pound-foolish. Adhesives are the cheaper option overall, and it’s not even close.

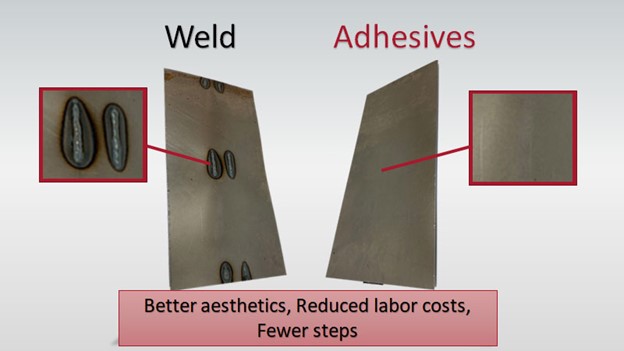

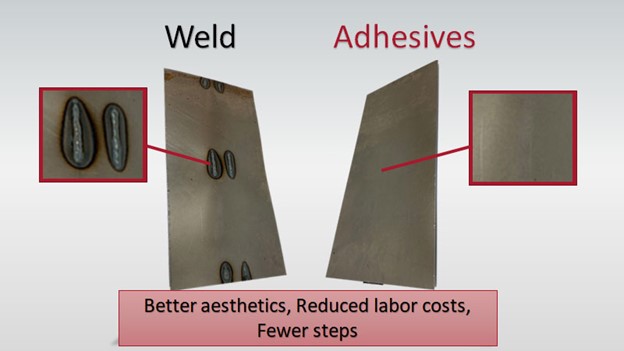

#2) Better Build Quality

On top of being cheaper, you can get a better build quality from adhesives for a variety of reasons. Adhesives don’t cause corrosion or heat distortion like welds can. Builds with adhesive bonds are also less brittle and more weatherproof creating a more durable end-product that can stand the test of time.

Also, welds only join material at certain points. With adhesives you can get a bond on the entire seam, effectively spreading out the bond strength, making your build more resistant to tearing and shearing forces.

Adhesives also allow you to join thinner materials while still maintaining the same bond strength. This allows you to effectively lightweight your end-product, making it faster, stronger, and more efficient. Whatever factor you need to optimize in your build, chances are adhesives can help you do it.

#3) Design Flexibility

Adhesives provide more design flexibility. With welding, you can only join surfaces in so many ways, and you’re limited to only using metal.

Using adhesives gives you more options when it comes to material choice and the types of joints you can use to bond those materials. You can join dissimilar materials and create connections in hard-to-reach spaces. And more options in design lead to better quality products at the end of production.

The Downsides of Welding

Regardless of the labor shortage, welding has always had a few limitations.

#1) It Takes Skill

If you rely on welding as a process, then your project timelines are subject to swings in the skilled labor market. And right now that’s a big problem for obvious reasons.

#2) It Takes Time

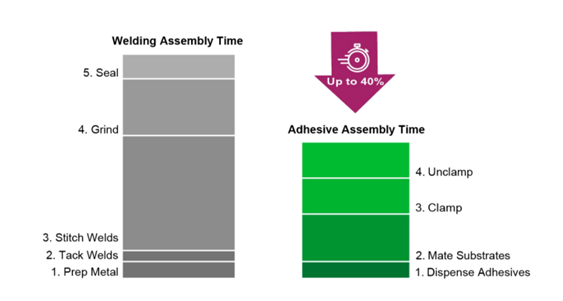

It takes time and care to weld something right. Welding involves surface prep, tack welds, stitch welds, grinding and sealing.

Adhesives are faster and require less effort. Just dispense the adhesive, bond your substrates, clamp, and then unclamp. And better yet, cure times on adhesives are quicker than ever. You no longer have to worry about waiting for bonds to cure before moving on to the next step in your assembly.

#3) Welding Can Be Overkill

At the end of the day, welding can be overkill for a lot of applications. Welding creates extremely strong bonds, but if your project only requires a certain bond strength, you don’t need to weld and create bonds that have double or triple the hold strength required.

Adhesives provide hold strengths that stand up to almost any specifications. There’s no need to overengineer.

Ways to Replace Welding in Your Processes

Every project is unique, but adhesives offer a great solution to reduce or even eliminate the need for welding in your production lines. When you decrease your reliance on welding, you decrease the need for skilled labor in a time where skilled labor is hard to find.

#1) Completely Replace Welding with Adhesives

In many cases, you can completely cut welding out of your assembly process. Today’s adhesives are so advanced that you can get all the benefits listed above while saving time and money.

Cutting welding out of your assembly process comes down to your own unique application. Making the change may be a bit of a process up front, but it will pay off in the long run. Take the time to consult with an adhesive expert. They can help show you where adhesives make the most sense in your process, recommend the right one to use, and help you source it.

#2) Supplement Welding with Adhesives

Sometimes there are things that need to be welded, and there are no other replacements. If this is the case for your application, then you can always find places to supplement welds with adhesives.

Minimizing welds allows you to get some of the cost and time savings of adhesives. It can also ease the bottleneck that your overworked welders may be experiencing. Take some of the burden off their hands with adhesives.

Conclusion

If you’ve ever considered switching away from welding, now’s the time. And at Chemical Concepts, we can help you make that switch.

We can give you a no cost, no risk assessment of your process and make recommendations on how to replace welding in your production lines. If you’re a manager or business owner, it’s incumbent on you to explore all possible avenues to save costs and increase production.