Tesa’s ACXplus – The Constructive Bonding Application Forerunner (Part II)

In Part I of our Tesa twin spin, we detailed three characteristics of the ACXplus suite of industrial constructive tapes that indeed set them apart from the rest of the field. Bonding power, stress dissipation, and weather resistance are all common to ACXplus tapes, and factors, as stated, that dictate their superior status when it comes constructive bonding. As review, we also covered the situations where these adhesives can best be used. They are:

In Part I of our Tesa twin spin, we detailed three characteristics of the ACXplus suite of industrial constructive tapes that indeed set them apart from the rest of the field. Bonding power, stress dissipation, and weather resistance are all common to ACXplus tapes, and factors, as stated, that dictate their superior status when it comes constructive bonding. As review, we also covered the situations where these adhesives can best be used. They are:

- Bonding transparent and translucent materials

- Bonding difficult-to-bond materials

- Bonding panels and reinforcement bars

With that in mind, now it’s time to get a bit more specific. In today’s blog, we’ll cover the tape classes, and a few of the individual products in this line of constructive bonders!

ACXplus – 705x – High Transparency

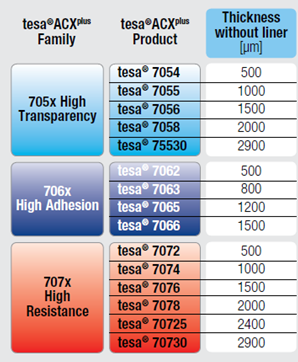

The ACXplus line of tapes is comprised of three classes. They are 705x, 706x and 707x. Each class has a variety of tape products, but each category itself has a specialty. 705x tapes are the ‘high transparency’ choice. This family of tapes offers virtually invisible bonding for transparent and translucent applications, or any application where optics are critical.

Recommended applications for 705x

- Partition walls

- Shower cabins

- Glass cabinets

- Bonding of glass or deco class panels with furniture, air conditioning units, or appliances

- Glass control panels on elevators or similar equipment

ACXplus – 706x – High Adhesion

Rigid adhesion comes into play when one is bonding difficult-to-bond materials. These are typically substrates with lower surface energy, like powder coated surfaces and certain types of plastic. In these types of environments, namely the bonding of powder coated panels, aluminum bumper rails, muntin window bars, switch cabinet panels, etc., the 706x class of adhesives is preferred.

707x – High Resistance

The 707x class of ACXplus tapes addresses the challenges of outdoor wear and tear, and indoor applications that are prone chemicals, solvents, and cleaning agents. This class is typically reserved for the bonding of panels and reinforcement bars in environments that test their strength and durability. 707x tapes should be used on the following applications:

- Bonding deco panels on exterior doors

- Wall cladding

- Elevator cabin panels and reinforcement bars

- Paneling used in the transportation sector (i.e. skeleton-structure mounts)

- Wood furniture panels

NOTE* – Each class of tape, as we mentioned, has several individual tapes which are essentially distinguished by their thickness. For instance, the ACXplus 7054 is the thinnest tape of its class at 20 mil. This could suit your situation, but if you wanted to double the thickness, you’d perhaps choose the 7055, which at 40 millimeters thick is double that of the 7054. This relationship applies for all three ACXplus classes.

Here is a visual representation of the classes and their thicknesses

We hope that you found our two-part blog on Tesa’s ACXplus tape informative and useful. If any questions arise, or you’d like to talk to a sales representative about the products we offer or your application, don’t hesitate to call or email!

800.220.1966 – [email protected]