7 Ways to Make Fabricating Porcelain Countertops Easier

Porcelain countertops are in high demand. This is good news and bad news for fabricators, who face a few challenges working with the material. In this post, we review 7 ways to make fabricating porcelain countertops easier.

Porcelain countertops are experiencing growing popularity with consumers.

And it’s easy to see why. Porcelain is extremely hard and scratch-resistant. It’s also stain-resistant and provides a high heat tolerance. And its high UV stability makes it suitable for outdoors, unlike engineered quartz. There are also many sintered stone products from brands like Neolith, Dekton and Lapitec with similar characteristics that are more and more prevalent in the marketplace.

But despite growing demand among consumers and dealers, many fabricators are reluctant to work with it. Cutting porcelain and sintered stone is difficult and requires specialized blades. And even though porcelain is hard, if it does break, it breaks like glass.

The good news is there are a number of strategies and solutions to make porcelain fabrication much easier.

Self-Anchoring Inserts

If you’re working with porcelain countertops, you will need a way to mount undermount sinks. You may also need a mechanical anchor for wall panels, fireplace surrounds and other projects as well.

The problem is that the mounting methods you typically use for granite won’t work for porcelain. Using lead anchors and epoxy might work for 30mm granite slabs. But this method is not practical for porcelain in the 8-20mm range.

Self-anchoring inserts like the Keep-Nut make mounting undermount sinks to porcelain much easier. The Keep-Nut is a self-anchoring, press-in, threaded insert that provides permanent threads in countertops or panels.

Keep-Nuts require a shallow drilling depth, only going in 6.5mm. And each insert provides 500-600 pounds of strength. Four Keep-Nuts alone can support the weight of a person.

You can use the keep-nut to horizontally or vertically mount porcelain for many applications:

- Undermount Sinks

- Building Facades

- Wall-coverings

- Furniture

- Fireplaces

Preparing and installing the Keep-Nut is easy and quick, making it easy for fabricators to mount porcelain.

Bonding Fasteners

For some applications, drilling fasteners into porcelain isn’t ideal. A 6mm slab of porcelain, for example is too thin for even the Keep-Nut. In these situations, you can use bonding fasteners to glue hardware to the porcelain.

Bonding fasteners like the Chem-Set™No Drill Anchors allow you to create male or female threaded attachment points on porcelain surfaces without drilling into the material. The bond is so strong it often exceeds the strength of the steel fastener. In fact, if you were to hit a bonded fastener with a hammer (if using the right adhesive), the hardware would fail before the adhesive.

Seaming Adhesives

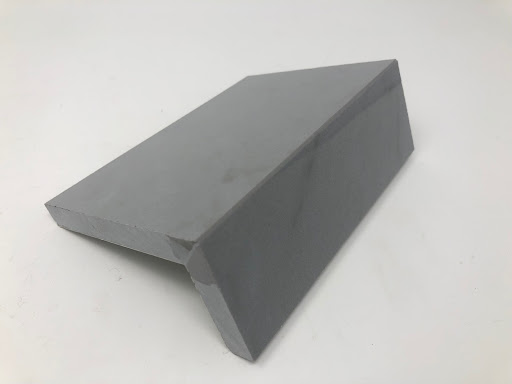

Many kitchen layouts will require a seam at some point and due to the available thicknesses, porcelain projects often involve miter edges to achieve the look of a thicker slab. The problem is that standard epoxies and polyester glues that are commonly used for granite simply do not bond well to porcelain. Using a seaming adhesive designed for porcelain will allow you to create perfect mitered edges and deck seams for every project. There are also UV-stable adhesives that can be used outdoors on exterior projects and can handle the sunlight without degrading or discoloration.

Hybrid Sealants

Hybrids sealants are silane-crosslinking organic polymers that combine properties typical of both silicone and polyurethane. A hybrid sealant provides both the adhesive

strength and paint-ability of polyurethane with the weathering resistance of silicones. The bond also eliminates their individual weaknesses.

In addition to creating strong bonds for porcelain countertops, a hybrid sealant also drastically speeds up the fabrication process. A regular silicone adhesive takes 24 hours to bond. In contrast, a hybrid sealant starts to grab in 45 minutes to an hour. This allows fabricators to get their porcelain slabs in place 24 times faster. Adhesives like this are commonly used to bond waterproof backer board like Kerdi Board or Wedi Board as a substrate under the countertop. Hybrid sealants offer much better performance for this application than silicone and are faster and easier to use than epoxies.

Porcelain Scratch Repair System

Porcelain is a strong and scratch-resistant surface. But it is possible for an object with equal or greater hardness to scratch it during use. Porcelain cookware and plates that drag on the countertop can scratch. And diamond jewelry and engagement rings will cut through any countertop with ease.

For any fabricator making the jump to porcelain, a scratch repair system is a must-have. It will allow you to remove scratches that otherwise might be impossible to repair. This repair system could save you from having to remake and replace an entire top, so this should definitely be in your toolbox in case of emergency. It will pay for itself in one use. If you have not seen a scratch repair on porcelain, you might want to see it to believe it!

Overhang Brackets

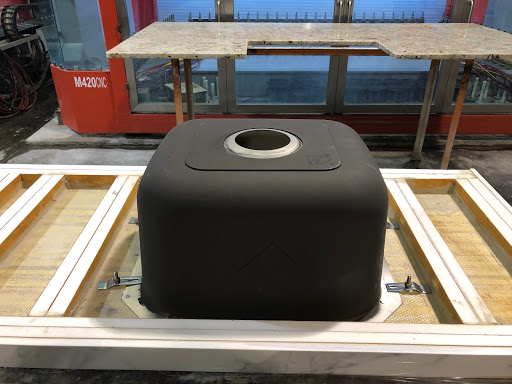

A common design porcelain fabricators can expect to work with is the floating countertop. But a floating countertop provides challenges when it comes to mounting.

You’ll need hardware and brackets strong enough to support the porcelain slab and any objects users might place on it. But traditional brackets that are visible to the eye will undermine the floating countertop aesthetic your customer is looking for. To maintain the floating aesthetic, you’ll need hardware that eliminates visible corbels and brackets.

Specialized overhang brackets like CounterBalance will provide enough support for porcelain countertops and allow a whole array design possibilities such as floating vanities, floating shelves, shower seats, raised bars and extended islands without interfering with the aesthetics of the end product.

|

|

Porcelain Sealer

Porcelain is nonporous, making it resistant to staining. However, some lower-quality porcelain products can be susceptible to staining and no surface is 100% stain proof. Red wine for example is a food product that may cause stains on some porcelain products if left too long on the surface.

You can help prevent stains with a porcelain sealer that does not allow water and oils to penetrate the surface. To seal porcelain, you’ll need a nanotechnology porcelain sealer with particles small enough to get into the microscopic imperfections in the surface.

Conclusion

Working with porcelain presents unique challenges to fabricators used to quartz and natural stone. Fortunately, having the right tools in place can make the process much m?subject=Porcelain easier. If you have questions about the products above or are looking for other solutions like these to make fabrication and installation easier, contact the product experts at Chemical Concepts today!