Conathane Products Offer Significant Advancement in Coatings and Compounds for Electronics Industry

Advancements in the electronics industry call for more potting/encapsulation systems that have the proper blend of stability, flexibility, and chemical resistance.

Chemical Concepts is now a proud distributor of Conathane products from Elantas PDG (who recently acquired Cytec Solvay Group).

As the electronics industry adopts surface mounting technologies and lead-free solder chemistries, rigid insulating potting/encapsulation systems are resulting in fracturing on circuit components and fatigue failure. Conathane® polyurethane potting products offer the perfect insulation solution in optimizing flexibility with structural stability and chemical resistance.

Conathane® products include:

- Polyurethane potting & encapsulation compounds

- Polyurethane conformal coatings

- Polyurethane tooling, casting and doming compounds

Let’s examine four of the top Conathane products that we now distribute.

Cytec/ Conap Conathane CE-1164 Polyurethane Conformal Coating

Conap CE-1164 is a single component, air-drying, room temperature curing, polyurethane conformal coating. This solvent-based coating is especially designed for thin-film applications on electronic components and printed circuitry. It was developed specifically to provide the ultimate in humidity resistance and hydrolytic stability, while retaining excellent flexibility to prevent fracturing of fragile components during thermal cycling. CE-1164 is a high-performance conformal coating specifically designed as an electrical insulating coating for printed circuitry and components.

Conap CE-1164 is a single component, air-drying, room temperature curing, polyurethane conformal coating. This solvent-based coating is especially designed for thin-film applications on electronic components and printed circuitry. It was developed specifically to provide the ultimate in humidity resistance and hydrolytic stability, while retaining excellent flexibility to prevent fracturing of fragile components during thermal cycling. CE-1164 is a high-performance conformal coating specifically designed as an electrical insulating coating for printed circuitry and components.

Cured films maintain excellent adhesion to phenolic and epoxy-glass laminates even in adverse environmental conditions. A tracer dye has been incorporated to aid inspection under ultraviolet light.

Conathane® EN-4 Part A Polyurethane Encapsulant Gallon

The Conathane EN-4 Polyurethane Resin System is a two component, non-MBOCA system that is used for molding and potting electrical assemblies that are exposed to extreme thermal changes. Customers find it to be especially suited for the protections of delicate electronic/electrical devices that must perform in hostile environments, especially underwater sound devices.

The Conathane EN-4 Polyurethane Resin System is a two component, non-MBOCA system that is used for molding and potting electrical assemblies that are exposed to extreme thermal changes. Customers find it to be especially suited for the protections of delicate electronic/electrical devices that must perform in hostile environments, especially underwater sound devices.

This product is typically used for print circuit boards, electrical cables, connectors, strain sensitive devices, and wire wound devices. It offers good dielectric properties, hydrolytic stability, low viscosity, high elongation, and resistance to fungus and thermal shock. Additionally, it is recommended for use as a molding and potting compound for general electronic use.

Cytec/Conap Conathane® UF-3 Polyurethane Encapsulant Gallon Kit

Conathane UF-3 is a unique polyurethane foam characterized by low vapor pressure. Unaffected by grease, oils, and most solvents, this product is ozone resistant, has excellent insulation characteristics, is dimensionally stable, and will not rot or mildew.

Conathane UF-3 is a unique polyurethane foam characterized by low vapor pressure. Unaffected by grease, oils, and most solvents, this product is ozone resistant, has excellent insulation characteristics, is dimensionally stable, and will not rot or mildew.

Conathane UF-3 is suggested for use in packaging electronic components and assemblies. When properly mixed and poured into a cavity, the liquid system expands to fill the void spaces and cures at room temperature. The foam then adheres firmly to most clean surfaces and will reduce weight by as much as 75 percent!

This product’s low moisture absorbing characteristics make it an excellent moisture vapor barrier. The foam produced has a free-blown density of 7.6 pounds per cubic foot.

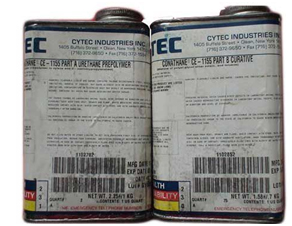

Cytec CONATHANE® CE-1155 Two Component Coating

Conathane CE-1155 is a two-component, solvent-based polyurethane printed circuit board coating designed for use in tough environments. The cured film is hard and tough and has excellent adhesion to phenolic and epoxy-glass laminates, plus it provides outstanding resistance to moisture and good abrasion resistance. When tested over printed circuit patterns, excellent results are obtained with 1.5 mil films.

Conathane CE-1155 is a two-component, solvent-based polyurethane printed circuit board coating designed for use in tough environments. The cured film is hard and tough and has excellent adhesion to phenolic and epoxy-glass laminates, plus it provides outstanding resistance to moisture and good abrasion resistance. When tested over printed circuit patterns, excellent results are obtained with 1.5 mil films.

Flexibility in application – Conathane CE-1155 may be applied by spray, dip, or brush techniques and will cure at room or elevated temperatures. The cured film is suitable for continuous operation up to 130°C. The system contains a fluorescent dye to aid inspection under ultraviolet light.

Are you interested in exploring the benefits that these new Conathane products offer? Our experienced sales team welcomes your call to discuss product recommendations. Just call us, toll-free, at 800-220-1966 or email us at [email protected]. We’ll be happy to help!